DEPARTMENT OF THE NAVY

HEADQUARTERS UNITED STATES MARINE CORPS

3000 MARINE CORPS PENTAGON

WASHINGTON, DC 20350-3000

NAVMC 4000.2

LPC

NAVMC 4000.2

From: Commandant of the Marine Corps

To: Distribution List

Subj: MARINE CORPS CLASS VIII MANAGEMENT HANDBOOK

Ref: (a) MCO 6700.5, MEDICAL AND DENTAL (Class VIII) MATERIEL

SUPPORT OF THE MARINE OPERATIONAL FORCES

1. Purpose. The Marine Corps Class VIII Management Handbook

provides guidance to Marine Forces on the execution of MCO

6700.5, Medical and Dental (Class VIII) Materiel Support of the

Marine Operational Forces.

2. Background. The Marine Corps is responsible for fulfilling

a capability for Class VIII materiel equivalent to 60 Days of

Supply (DOS). The Class VIII Management Handbook describes the

process and procedures of the Marine Corps to manage Class VIII

materiel, to establish a surge capability equivalent to 60 DOS,

and to fulfill re-supply capability requirements equivalent to

61-180 DOS. The Handbook provides detailed guidance on actions

required to effectively execute the Class VIII management roles

and responsibilities established in MCO 6700.5.

The Class Management Handbook describes the actions required to

manage the commodity through seven core functions: Management,

Requirements Determination, Selection Criteria, Sourcing,

Positioning, Acquisition, and Distribution. These functions are

consistent with the War Reserve Materiel Program, of which Class

VIII materiel is a component.

The seven core functions are also in line with the Military

Health System/Medical Logistics Enterprise processes used by

Navy Medical Logistics Command (NAVMEDLOGCOM) to determine

medical support requirements.

DISTRIBUTION STATEMENT A: Approved for public release;

distribution is unlimited.

Class VIII Management

i

NAVMC 4000.2

Marine Corps

Class VIII Management

Handbook

Class VIII Management

ii

Table of Contents

Overview......................................................iii

Management....................................................1-1

Requirements Determination ...................................2-1

Selection Criteria ...........................................3-1

Sourcing......................................................4-1

Positioning...................................................5-1

Acquisition ..................................................6-1

Distribution .................................................7-1

Marine Forces Reserve (MARFORRES).............................8-1

Systems Descriptions..........................................9-1

AMALs/ADAL Set List..........................................10-1

Acronyms & Definitions.......................................11-1

Class VIII Management

iii

Overview

The Marine Corps is responsible for fulfilling a capability for Class

VIII materiel equivalent to 60 Days of Supply (DOS). For policy level

guidance on Class VIII managements see MCO 6700.5.

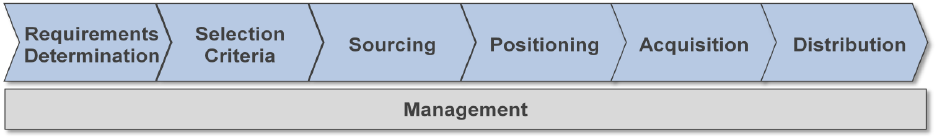

This chapter describes the actions taken by the Marine Corps to manage

Class VIII materiel, to establish a surge capability equivalent to 60

DOS, and to fulfill re-supply capability requirements equivalent to

61-180 DOS. The actions will be presented in terms of how they relate

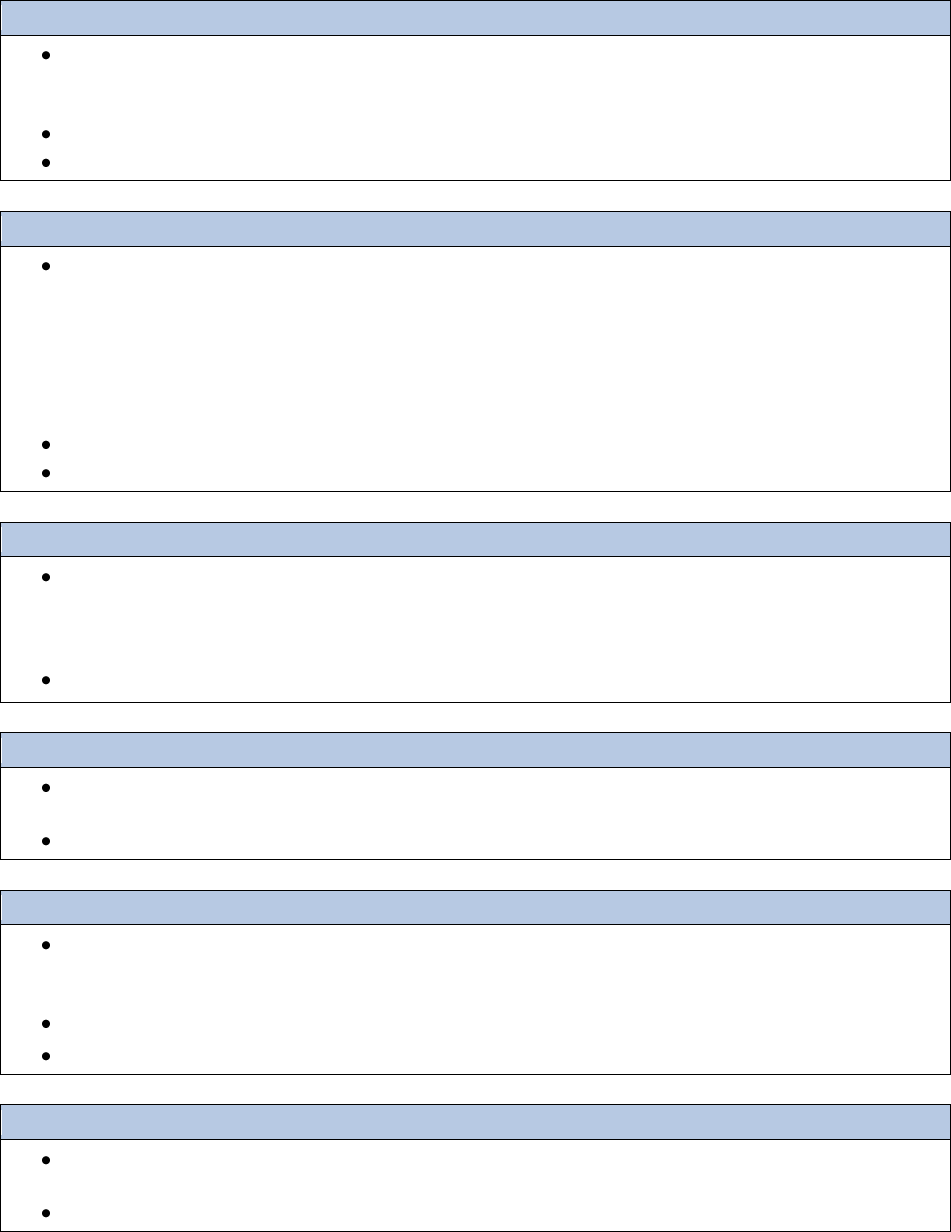

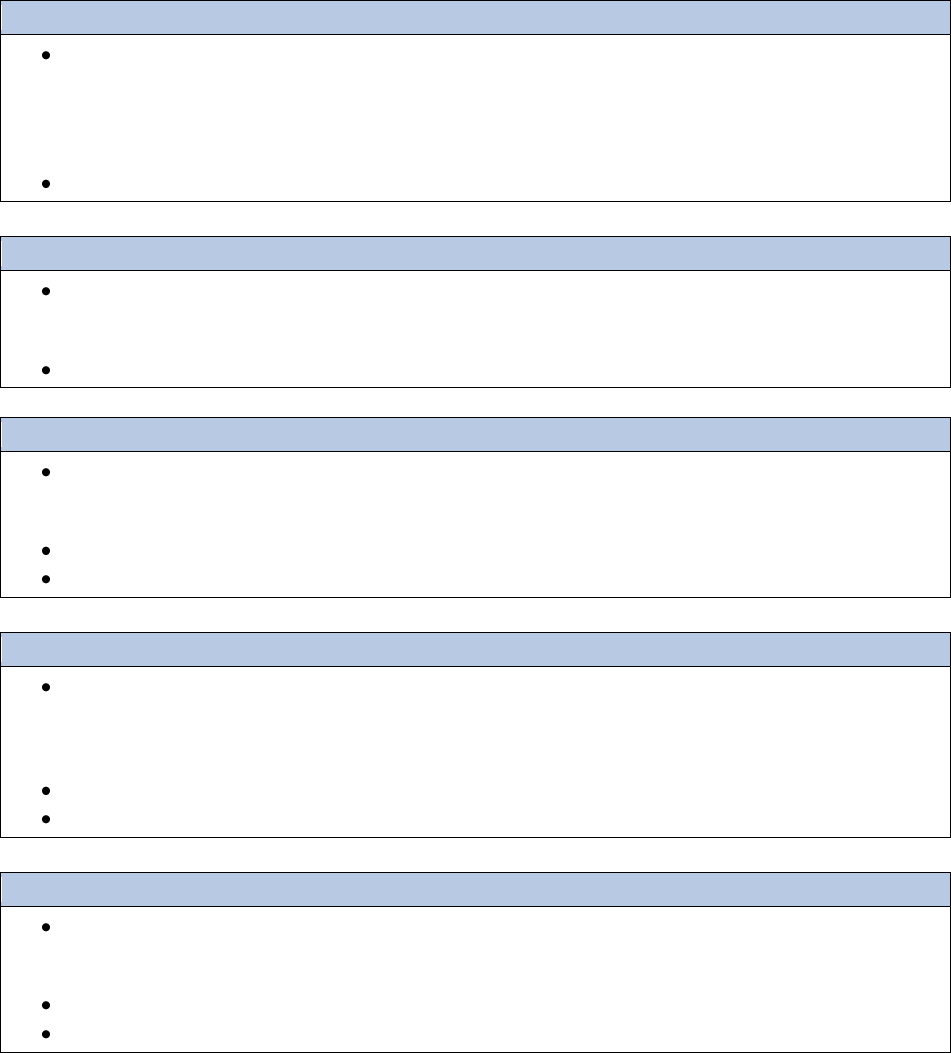

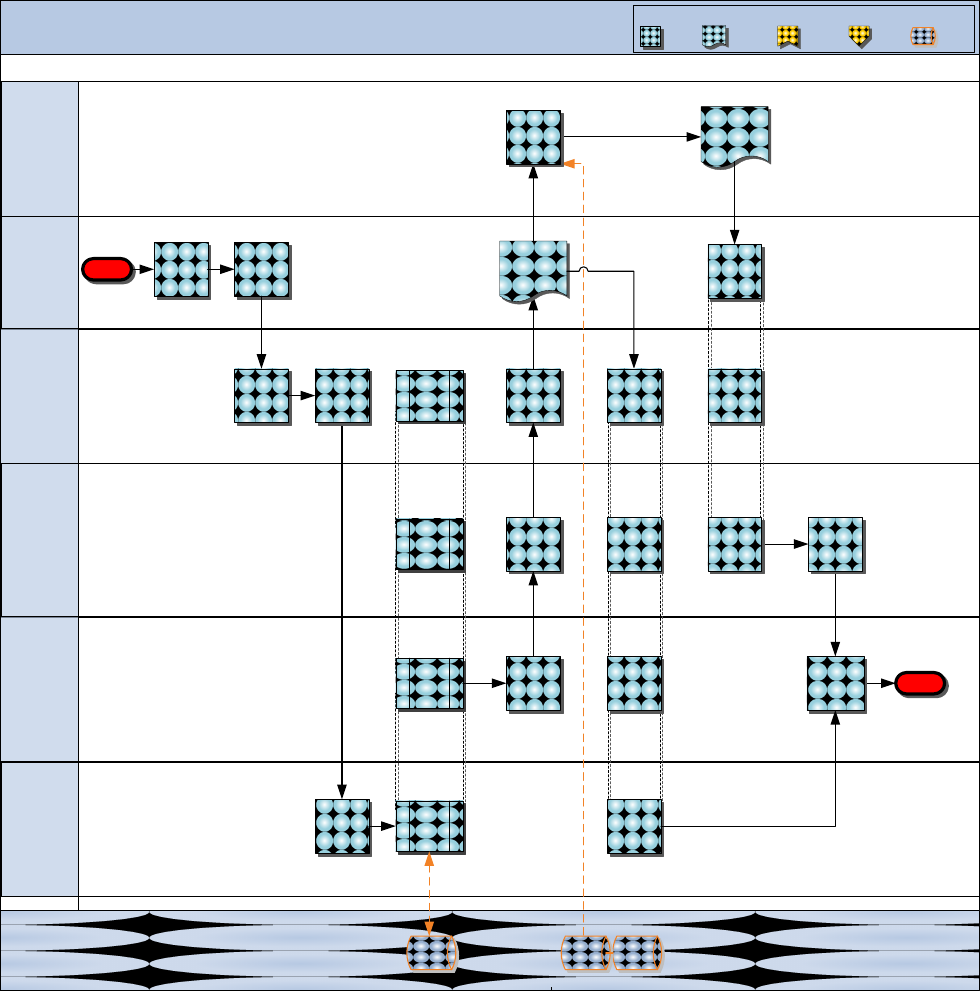

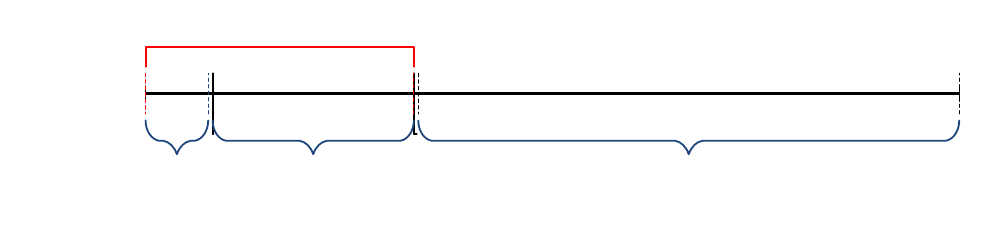

to the War Reserve Materiel (WRM) Functions, shown below.

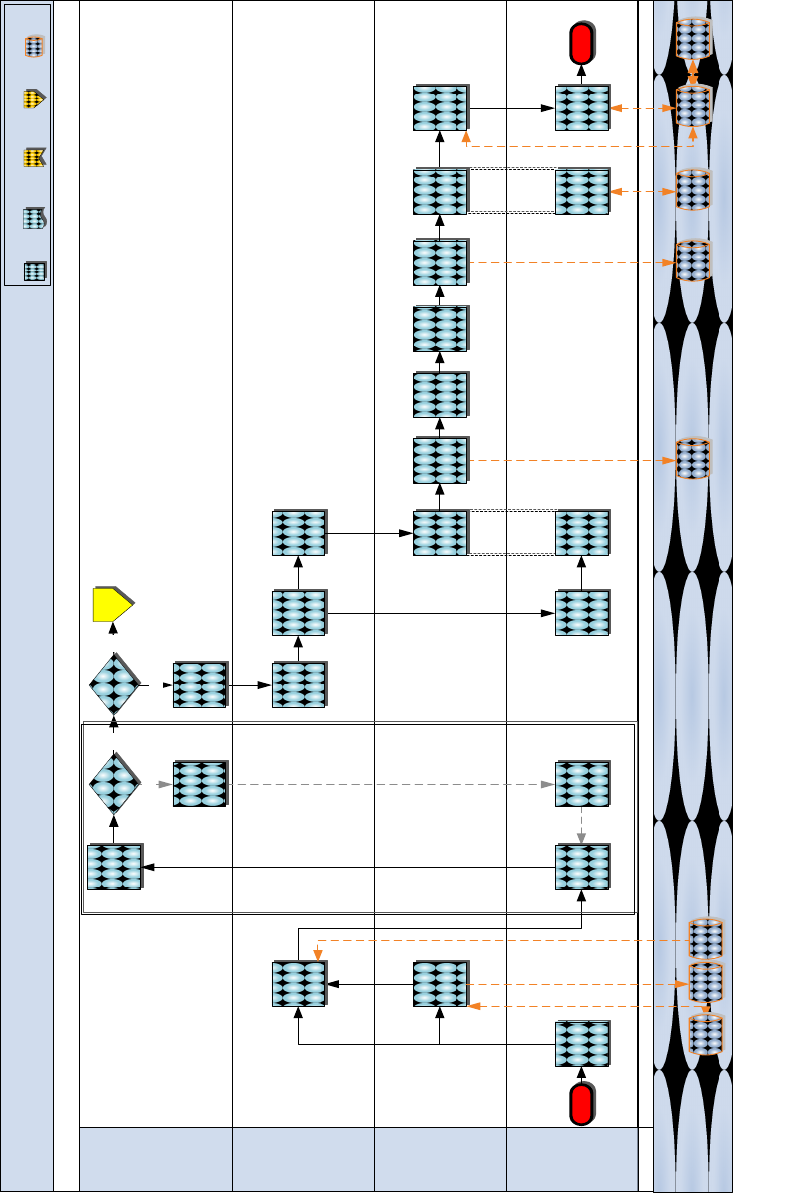

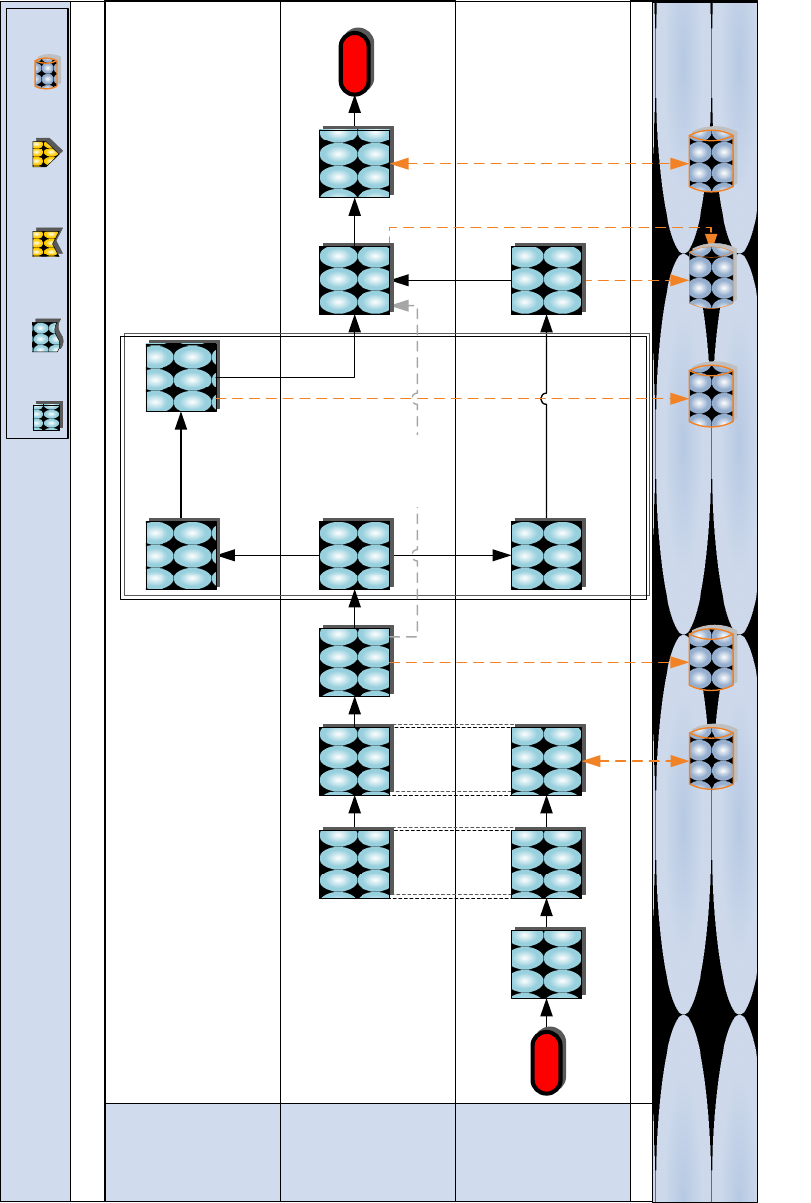

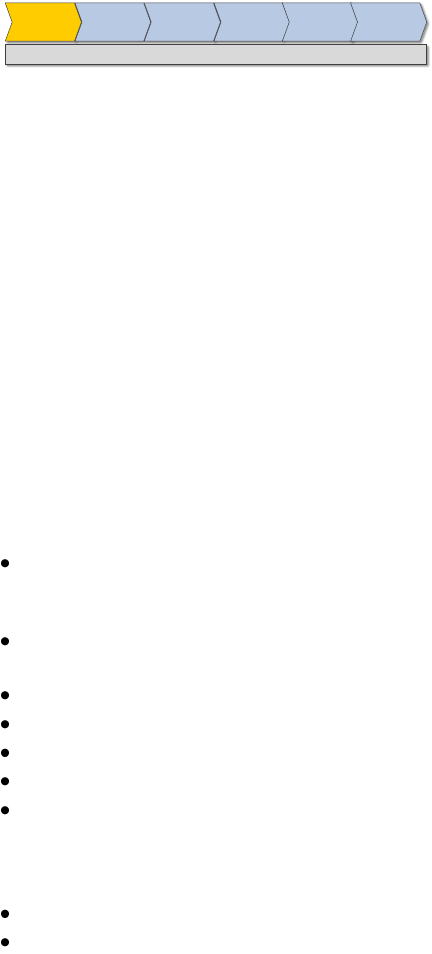

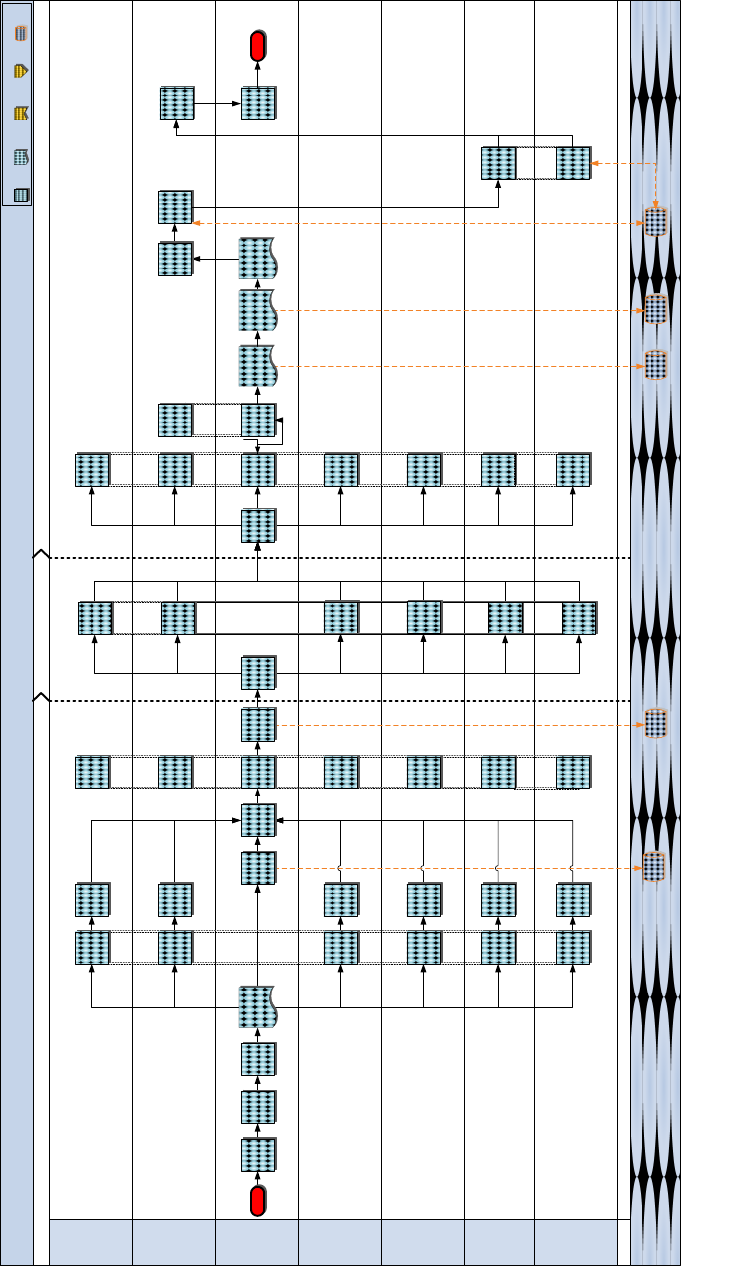

Figure 8.1 WRM Functions

Although the WRM Functions are executed separately, they are mutually

supporting activities. Additionally, these functions are in line with

the Military Health System/Medical Logistics Enterprise processes used

by Navy Medical Logistics Command (NAVMEDLOGCOM) to determine medical

support requirements. Of note, the final Disposition phase of the

NAVMEDLOGCOM process is not represented in the WRM Functions.

Class VIII Management

1-1

NAVMC 4000.2

Class VIII Management

Management

Chapter 1

Class VIII Management

1-2

Table of Contents

A. Management ................................................1-3

1. Recurring Management Activities..........................1-3

2. Inventory Process........................................1-6

Pre-LTI Procedures.......................................1-8

Post-LTI Procedures.....................................1-18

3. Proper Care and Storage of Pharmaceuticals..............1-23

4. CBRN Materiel Management................................1-24

5. Biomedical Equipment Management.........................1-25

Class VIII Management

1-3

A. Management

The Marine Corps manages the majority of Class VIII assets at the

individual Medical Logistics Companies (MEDLOGCOs), Supply Battalion.

MEDLOGCOs are required to maintain the Authorized Medical Allowance

Lists/Authorized Dental Allowance List (AMALs/ADAL) for the respective

Marine Expeditionary Force (MEF). The authorized lists are associated

with the approved Table of Equipment (T/E) established by Deputy

Commandant Combat Development & Integration (DC CD&I) based on the

Marine Requirements Oversight Council’s approved scenarios. Although

the T/E is assigned to the MEFs, the MEDLOGCOs are the custodians for

the equipment and consumables. The MEFs can draw against available

assets held by MEDLOGCOs, as needed.

Additionally, MEFs are responsible for managing Class VIII Chemical,

Biological, Radiological, Nuclear (CBRN) materiel in collaboration

with Marine Corps Logistics Command (MCLC). MEFs maintain all Class

VIII CBRN materiel as individual line items, rather than as configured

AMALs, at the quantities required to support a force employment

package. MEFs source their Class VIII CBRN requirements through a

combination of in-stores assets or through the use of existing DLA-

managed contingency contracts. It is important to note that MEFs do

not manage CBRN decontamination kits. (See Chapter 1.4. for more

information on management of CBRN assets).

1. Recurring Management Activities

There are several additional management activities required to

maintain Class VIII materiel. The purpose and impact of these

activities are explained below.

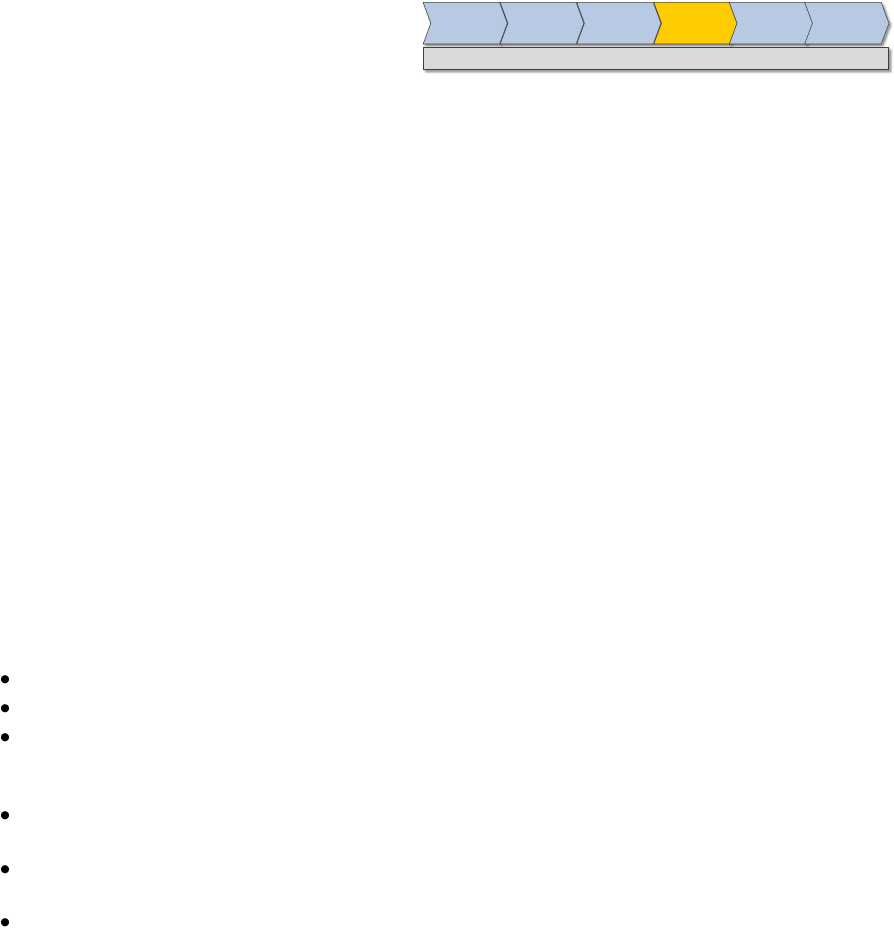

Selection

Criteria

Requirements

Determination

Sourcing Positioning Acquisition Distribution

Management

Accountability

AMALs/ADALs are organic assets to the Marine Corps and apart of the

T/E. As with other T/E items they are required to be accounted. The

Marine Corps has designated the Total Force Structure Management System

(TFSMS) as the information system to account for T/E quantities.

MEDLOGCOs are required to maintain accountability of AMALs/ADAL

inventory through Defense Medical Logistics Standard Support –

Assemblage Management Module (DMLSS-AM) and in Global Combat Support

System-Marine Corps (GCSS-MC) (or SASSY, as applicable).

MEDLOGCOs are also responsible for maintaining all records concerning

inventory adjustments and materiel dispositions for a minimum of two

years and financial records for a minimum of 6.25 years.

MEDLOGCOs will conduct a wall-to-wall inventory reconciliation of all

standardized configuration and line item AMALs/ADAL at a minimum of one

time per year. During this time, all assets will be marked as deployed

or stored in the DMLSS-AM in order to initiate the physical count of

Class VIII Management

1-4

all materiel. The current AMALs/ADAL list can be found on Medical

Logistics Online (MLO).

Reference: Visit https://ips.usmc.mil/sites/mefkb/default.aspx for

current AMALs/ADAL line list; see MCO P4400.151B for procedural

inventory and accounting guidance; and see the ―Assemblage Management

(AM) section,‖ in NAVMC 4000.3 for DMLSS assemblage management

guidance. Additionally, see DoD Financial Management Regulation Vol. 5,

Chapter 21.

Important Note: Standardly configured AMALs/ADAL will be inventoried as

a configured assemblage with supporting documentation (e.g., inventory

list, packing list, etc.)

AMALs/ADAL Configuration

AMALs/ADAL are modularly configured in standardized configurations to

minimize deviations for embarkation and transportation requirements.

In addition to the obvious benefit of optimizing cube and weight, the

AMALs/ADAL, when appropriate, are packaged to optimize employment of

health services. Based on those benefits and Global Sourcing

requirements, it is imperative that the MEDLOGCO maintain the

AMALs/ADAL in their approved configurations. Failure to configure in

the manner prescribed by Marine Corps Systems Command (MCSC) may result

in improper employment of the AMALs/ADAL to facilitate Global Sourcing

efforts.

AMALs/ADAL are issued in complete blocks only; partial blocks are not

authorized. If a requesting unit requires supplemental equipment or

consumables not provided in the standard AMALs/ADAL block, then it is

the responsibility of the requesting unit to fund and request the

additional order.

Exception: Some equipment and supplies may be maintained as line items

to facilitate stock rotation and maintenance (i.e., expiration date

management for pharmaceuticals and battery recharging for equipment).

Reference: https://ips.usmc.mil/sites/mefkb/default.aspx; NTTP 4-

02.1, 3.3.3.4; ―Assemblage Management (AM)‖ section in NAVMC 4000.3.

Important Note: The Marine Corps standardizes across services to the

best of its ability; however, maintaining alignment with the Marine

Corps mission and mission-specific requirements receives higher

precedence than joint standardization. MCSC is responsible for service

standardization, which is conducted through the Defense Medical

Materiel Program Office (DMMPO) and Assemblage Life Cycle Management

(ALCM).

Class VIII Management

1-5

Medical Materiel Recalls

All equipment and pharmaceuticals that are under recall and/or have

problems that cannot be fixed by Bio-Medical Equipment Technicians

(BMET) will be announced via message from the US Army Medical Materiel

Agency (USAMMA) website. In special cases in which there is a risk to

life, a special Naval message and a MARADMIN will be released.

Reference: http://www.usamma.army.mil

Database Management

The Marine Corps Enterprise Software Portfolio contains Commercial Off

the Shelf (COTS), Government Off the Shelf (GOTS), and joint software

applications used within the Marine Corps Enterprise. For ease of

categorization, software applications are divided into functional

areas. The Marine Corps is considered a stakeholder in these functional

areas and is therefore responsible for maintaining a USMC software

portfolio in the Department of the Navy (DON) Application and Database

Management System (DADMS). DMLSS is included in the USMC software

portfolio and is therefore a system for which the Marine Corps is

required to maintain an Authority to Operate (ATO).

Guaranteed Returns Program

Guaranteed Returns Program is for Class VIII consumables and equipment

that are at or near their expiration date and have not had their

manufacturer seal tampered with or broken. The consumables in question

can be returned to the manufacturer for a replacement of the same

medicine or equipment.

Shelf Life Extension Program

Shelf Life Extension Program (SLEP) should be used whenever there is a

justification. All desired perishable pharmaceuticals should be

identified 210 days prior to the end of shelf life so they can be

vetted through the proper chain of command.

Reference: See Navy BUMED 6710.62A for criteria and instructions.

Class VIII Management

1-6

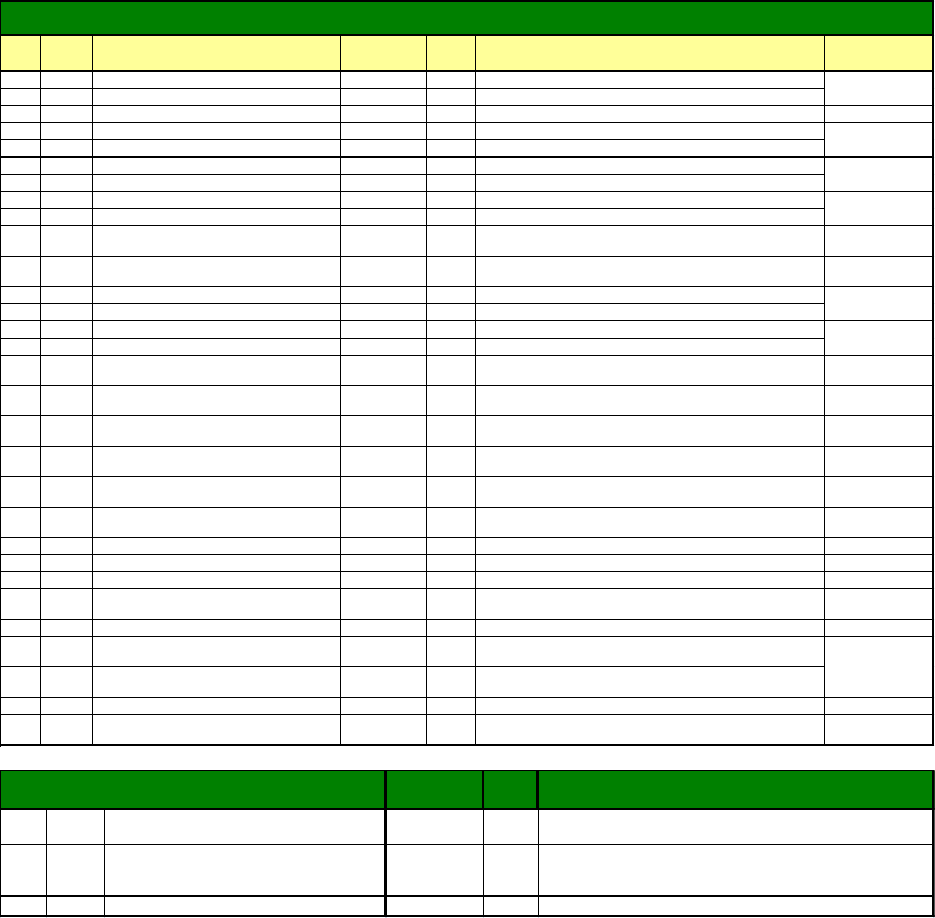

Figure 8.2 Class VIII Management Activities Process Descriptions

2. Inventory Process

The MEDLOGCOs are responsible for ensuring that proper equipment and

consumables are present or available to deliver the appropriate

capability of health services. Multiple management activities exist to

aid this process, including the accountability procedures, AMALs/ADAL

configuration standards, attainment reporting, capability analysis,

database management, guaranteed returns program, regular inventories,

medical materiel recalls, and Shelf Life Extension Program described

in the tables above. Maintenance and sufficient supply of equipment

and consumables are also achieved through an inventory process

facilitated by medical databases such as Defense Medical Logistics

Standard Support (DMLSS) and Medical Logistics Online (MLO), as well

as through Limited Technical Inspections (LTIs).

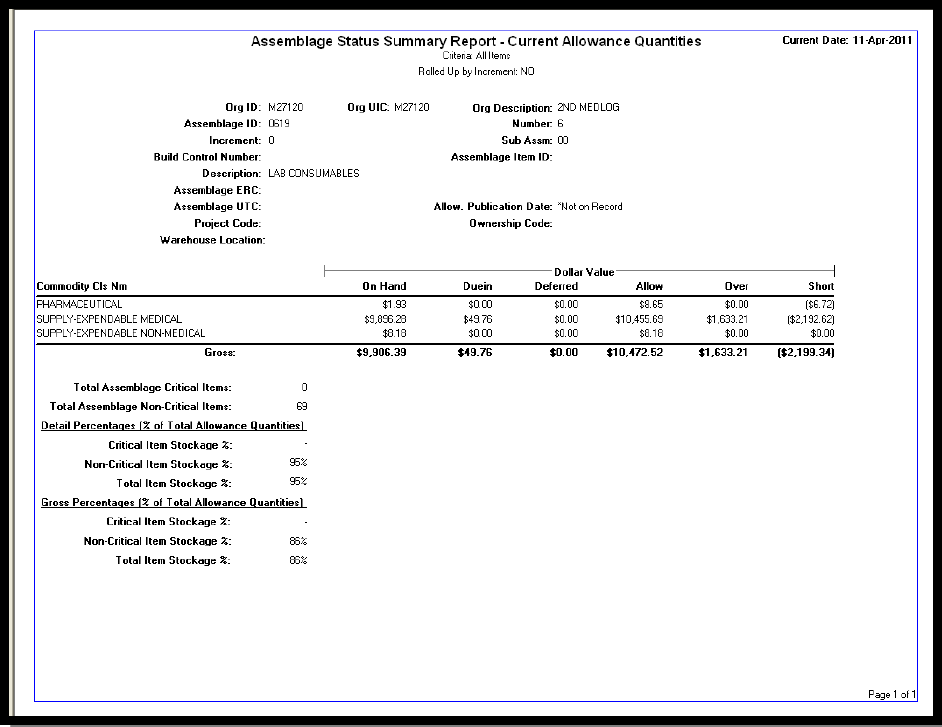

DMLSS provides access to the Packing List, Replenishment Process,

Assemblage Status Summary Report Criteria, and Assemblage Status

Summary Reports (see example in Chapter 1.d.), which can be used to

identify deficiencies or excess items. Additionally, upon receipt of

a line list from MCSC after Modernization Review, MEDLOGCOs use DMLSS

to generate manual DUE-INs by line item, which update as each item is

received and associate items to the appropriate blocks. Of note,

blocks that are out for exercises, operations, or deployments must be

deselected to allow for accurate updating of the system when those

blocks are returned. For additional information on how to complete

the inventory process, please see the NAVMC 4000.3 and

https://jml149.dmlss.detrick.army.mil/DMLSSU/, which offers DMLSS

training modules.

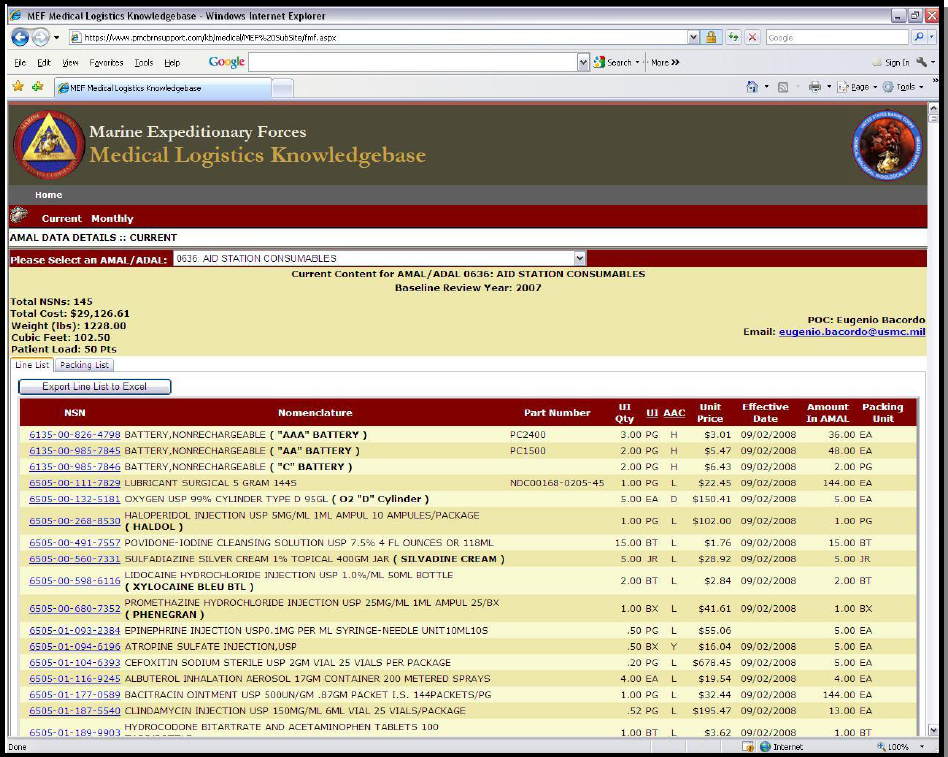

MEDLOGCOs can use MLO to view both the current list, which displays

new items or item increases from UDR updates, and the proposed list,

which shows replacements and new and increased items based on the

Modernization Review. Once items are purchased for the proposed list,

Receipts

Upon receipt of allowance materiel, custodians will check all items to

determine necessary storage requirements. Manufacturer guidance should

be followed in the storage requirements associated with medical

materiel. Environmental recommendations (i.e., temperature, humidity)

related to the storage requirements should also be followed to ensure

shelf life of the materiel (please see Chapter 1.3 for additional

information).

Reference: Regulations pertaining to security and inventory of

controlled substances, precious metals, pilferable items, and other

security type items are contained in NAVMED P117, Chapter 21, Section

2. Federal Supply Catalog information contained DoD 4100.39M, Volume 1

includes information reflecting security type items, special storage

codes, and shelf life codes to be observed.

Class VIII Management

1-7

MLO will promote from ―proposed‖ to ―current.‖ MARCORSYSCOM will then

send a spreadsheet list of items purchased to the respective MEDLOGCO

in preparation for delivery, and the MEDLOGCO will enter the purchased

item information into DMLSS as described above. MLO capabilities

allow MEDLOGCOs to view changes either in the past month or the past

six months to limit inventory workload.

For additional information regarding viewing and managing UDR and

replenishment items in DMLSS, please see the “Standard Assemblage

Update” and “Searching for Replenishment Items” sections of the NAVMC

4000.3.

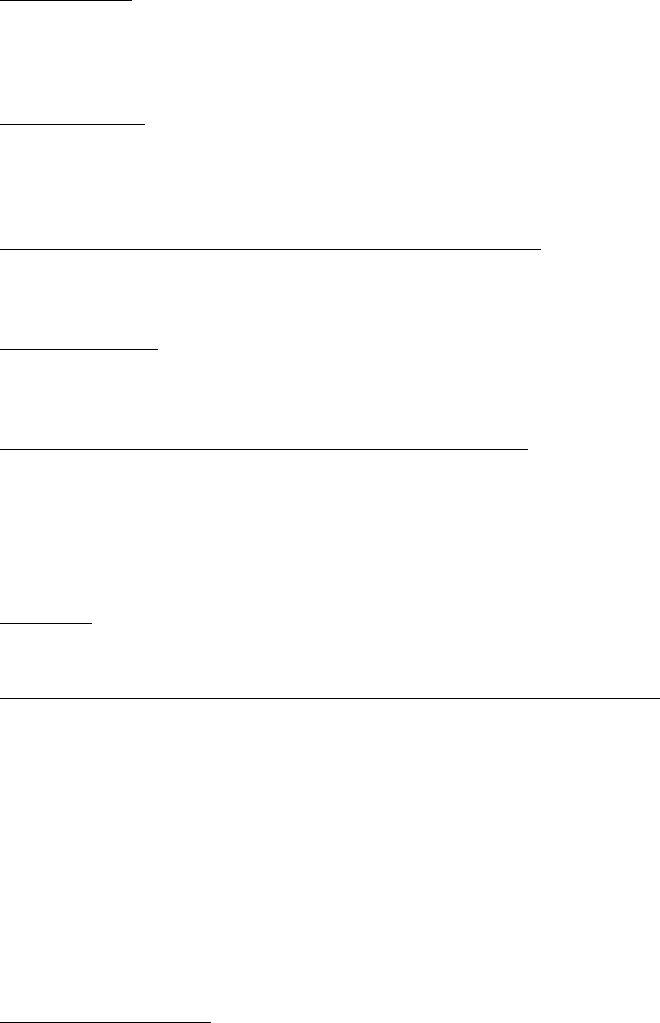

a. Medical Logistics Online (MLO) AMALs/ADAL List (SAMPLE)

Class VIII Management

1-8

Additionally, Limited Technical Inspections (LTIs) ensure proper

equipment, consumable, and health service delivery. There are two

forms of LTI: Pre-LTI and Post-LTI.

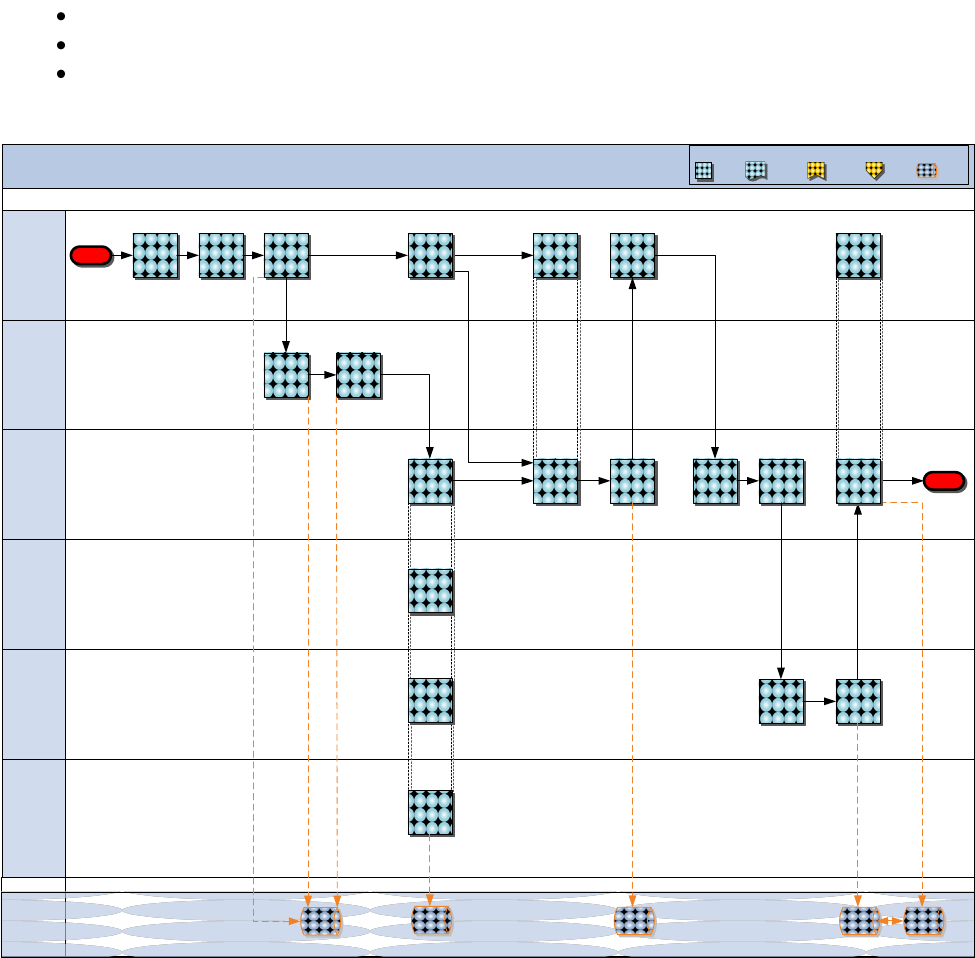

Pre-LTI Procedures

Pre-LTI procedures are performed prior to any issuing of AMALs/ADAL in

order to ensure that all equipment and consumables are accounted for

and in good working order.

Participants in this phase are:

Marine Expeditionary Forces (MEFs)

Marine Forces Reserve (MARFORRES)

Marine Logistics Group (MLG)

Medical Logistics Company (MEDLOGCO)

Requesting unit

Systems in this phase are (See Chapter 9 for Systems Descriptions):

Defense Medical Logistics Standard Support—Assemblage Management

Module (DMLSS-AM)

Global Combat Support System-Marine Corps (GCSS-MC)

See the Useful Reports section in the NAVMC 4000.3, for additional

information to aid the Pre-LTI process.

Class VIII Management

1-9

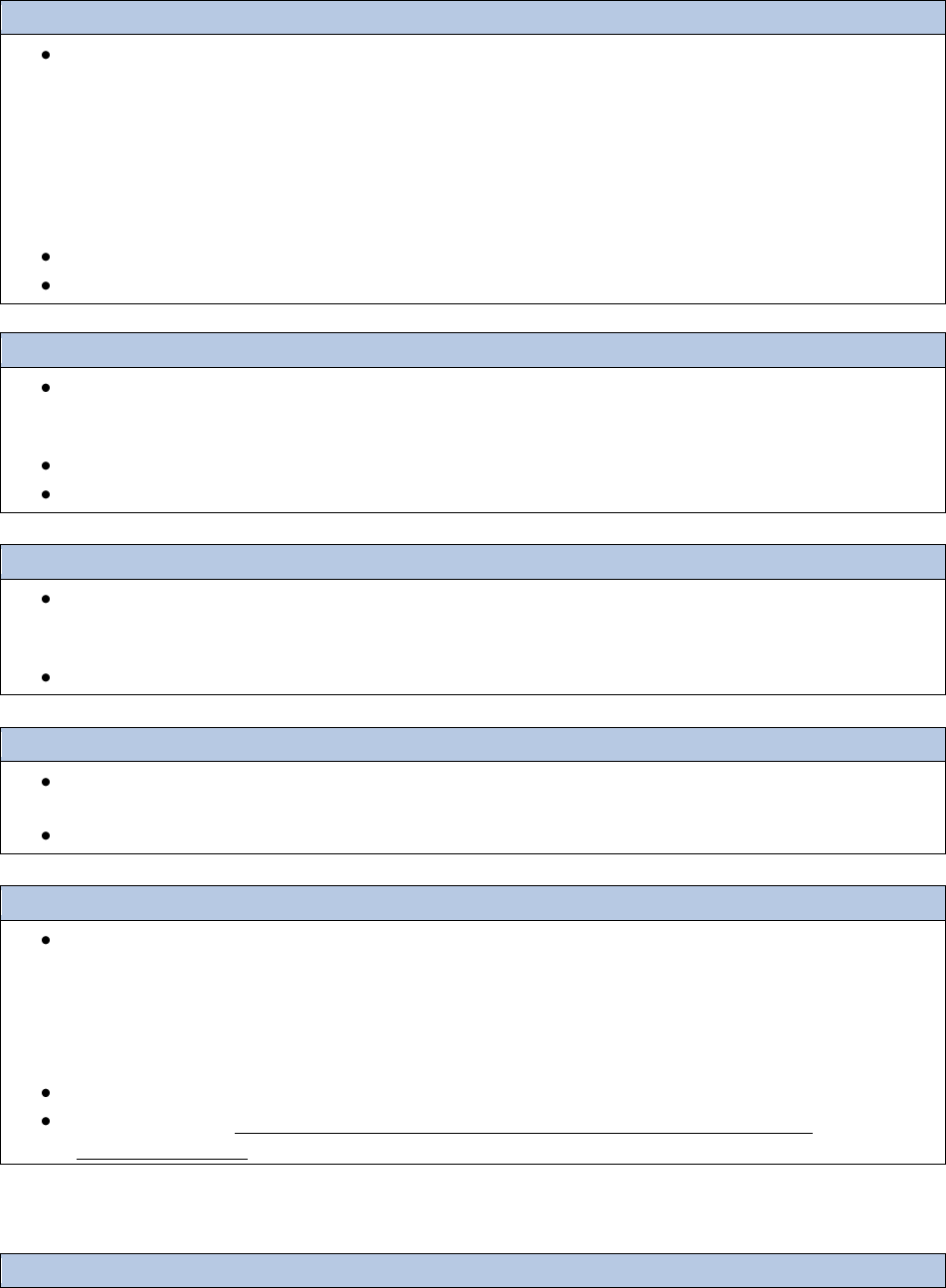

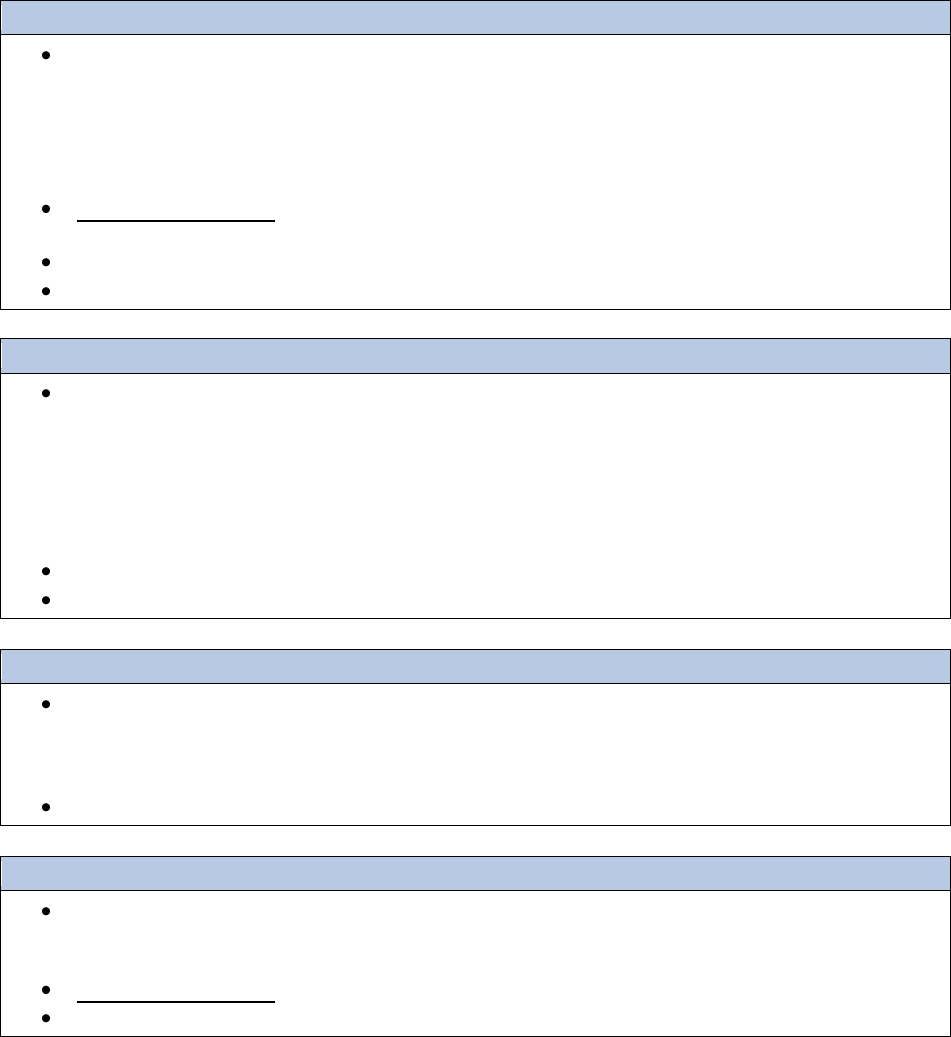

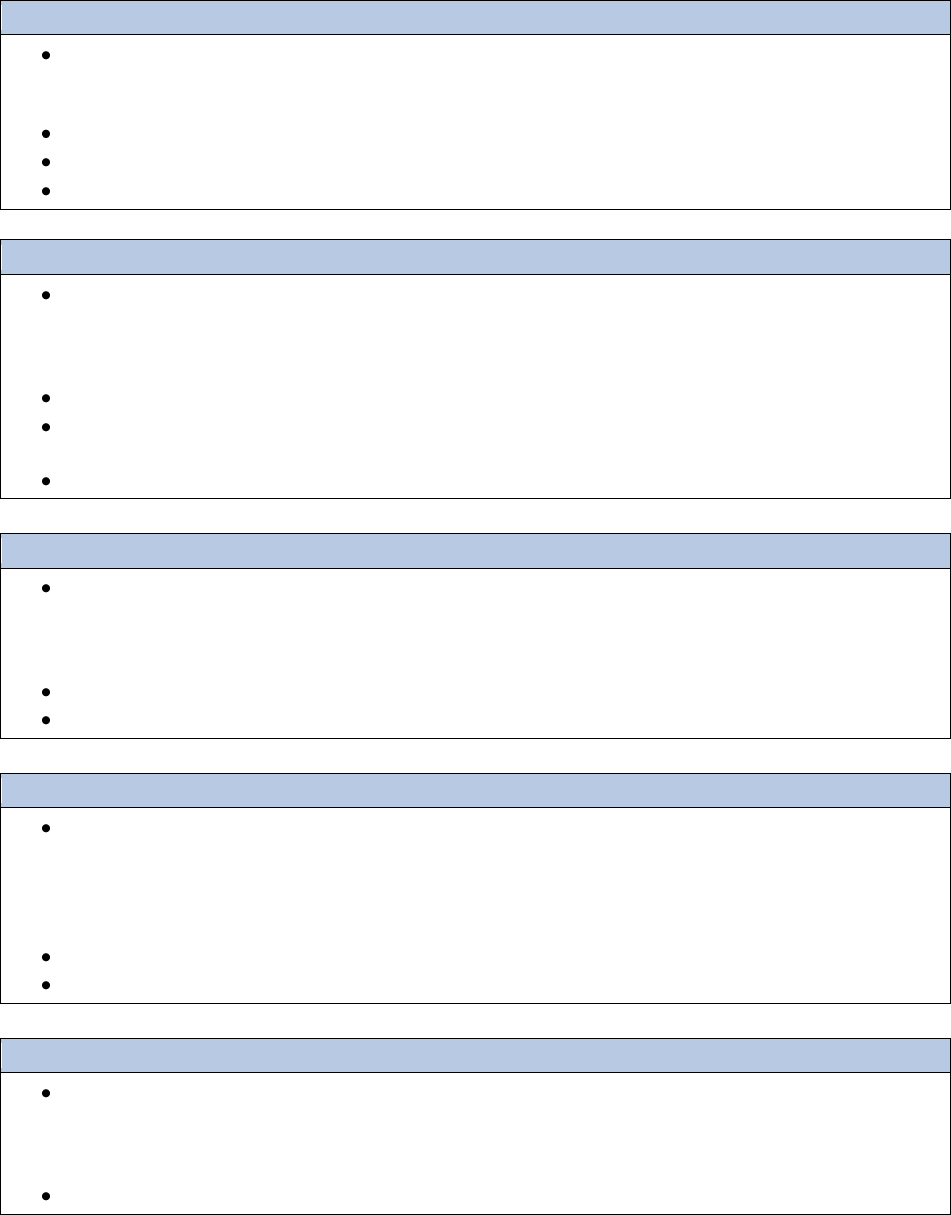

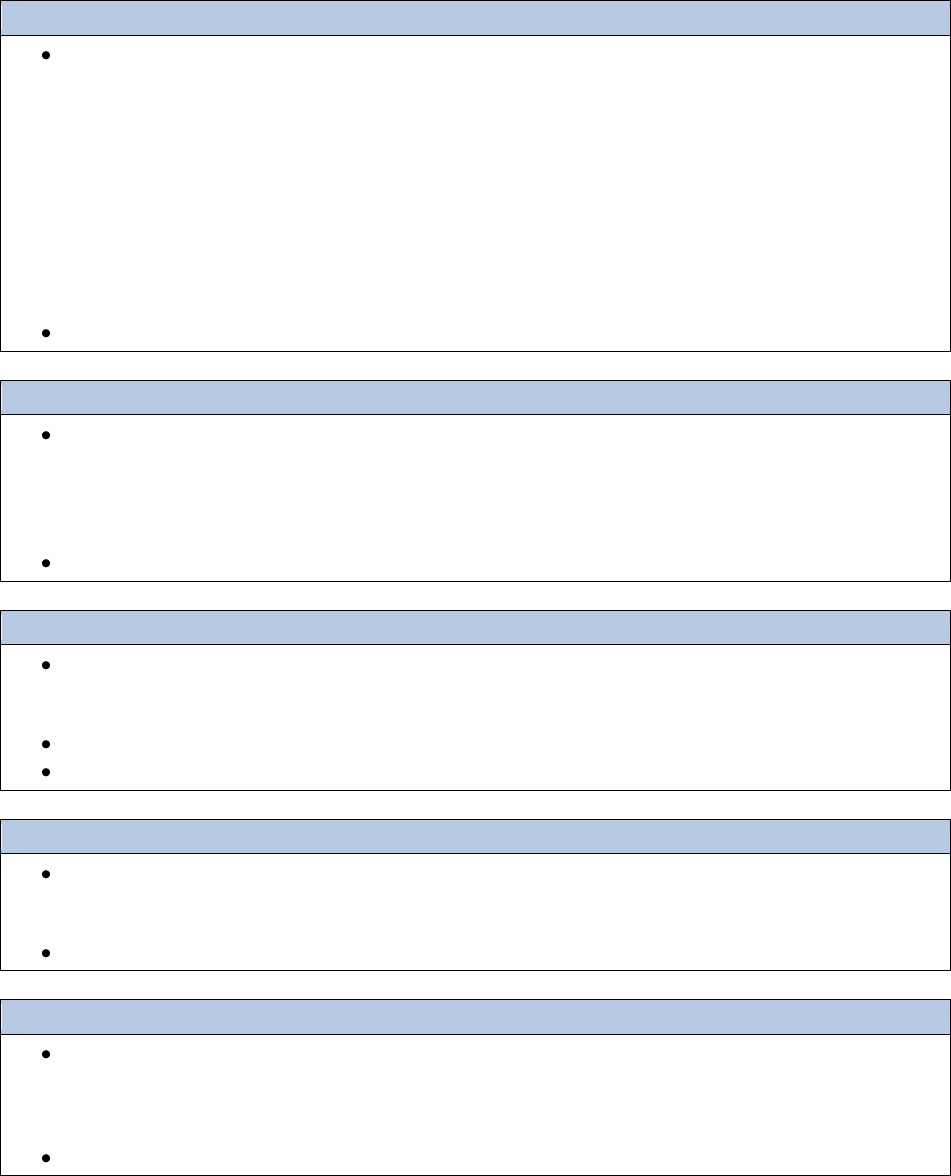

a. Process Map

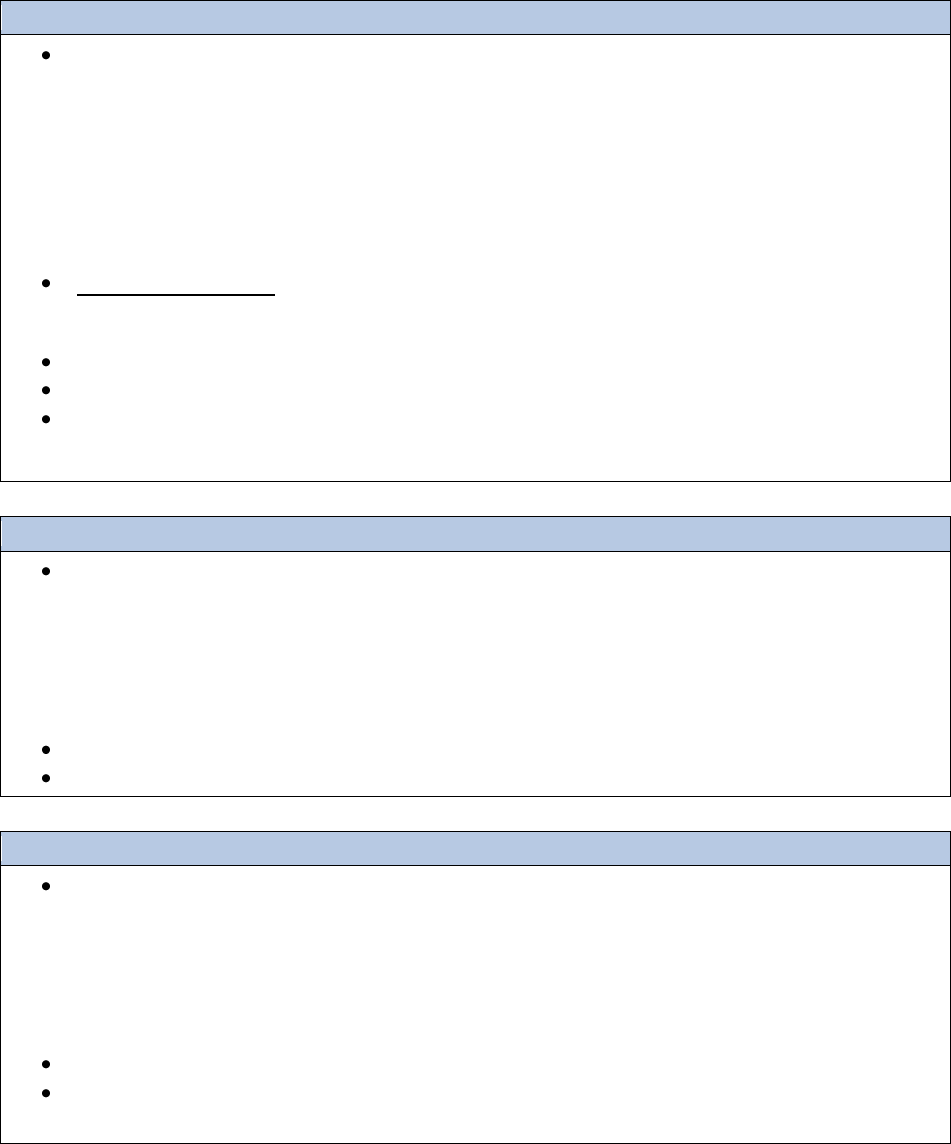

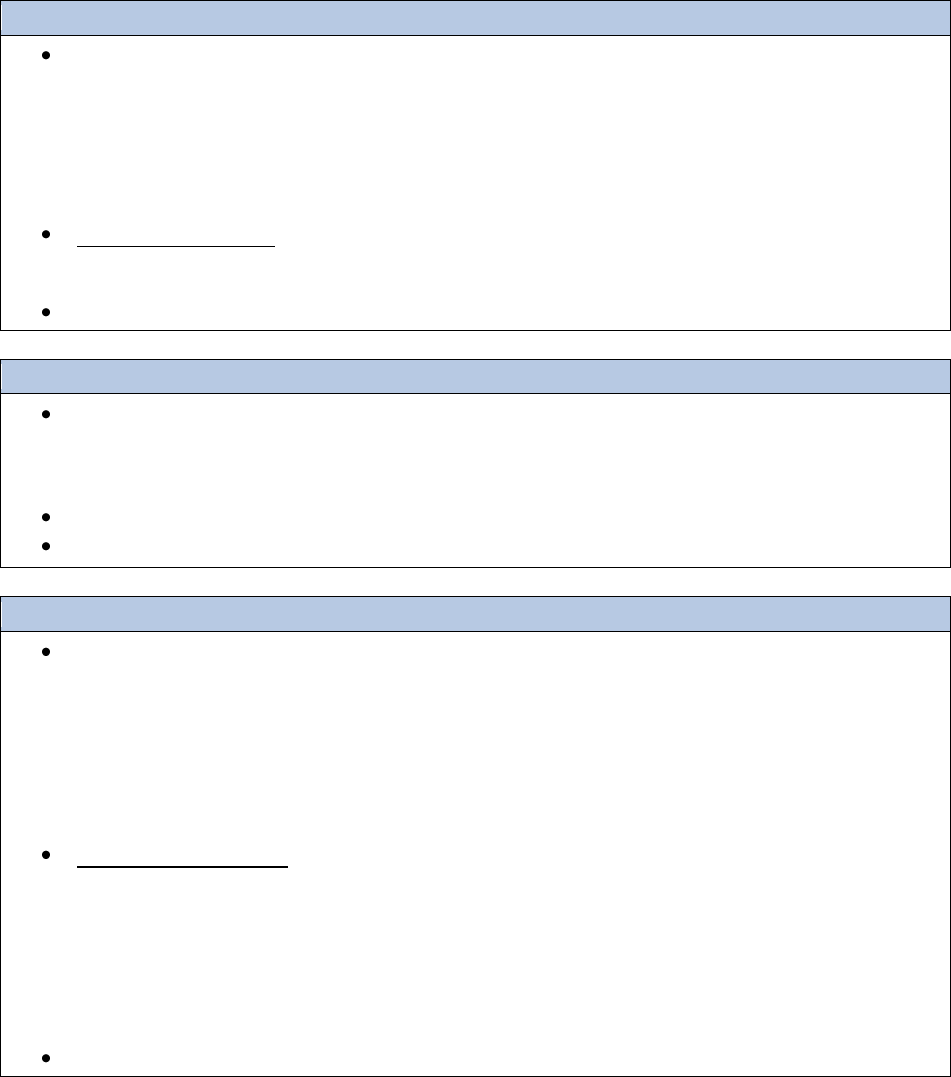

Figure 8.3 Pre-LTI Process

Pre - LTI Procedures

MEDLOGCO

System

Unit

(Requesting/

On-boarding)

MSC / MLG

MEF/ MARFORRES

DMLSS-

AM

Conduct

Asset Review

Review

AMALs/ADAL

Status

Order

deficiencies

DMLSS-

AM

Coordinate to

schedule Joint

LTI

Coordinate to

schedule Joint

LTI

DMLSS-

AM

Pull AMALs/

ADAL

No

Yes

Reject

request and

send back to

Unit

Modifies

request for

resubmission

Approve?

Notify unit of

request

approval

Task

designated

office to

support

request

Task Class

VIII support

Receive task

and prepare

to provide

support

Receive

notification

SASSY

Receive

materiel

request

DMLSS-

AM

Review request

& verify the

requesting unit

rates the

materiel

Review request

& determine

AMAL/ADAL

deficiencies

Refine &

submit

materiel

requirements

request

Start

Conduct Joint

LTI )

Conduct Joint

LTI

TFSMS

This portion of the process is continuous until

request is approved

Submit

preliminary

materiel

requirement

request for

coordination

Transfer

AMALs/ADAL

to unit & drop

asset in

records

Pick-up asset

in records

GCSS-

MC

TFSMS

End

Is global

sourcing

required

No

Reference

Global

Sourcing

Process

Yes

Process

Step

Document System

Previous

Phase

Key:

Next

Phase

Class VIII Management

1-10

b. Process Step Descriptions

1. Submit preliminary materiel requirement request for coordination

Description: For pre-coordination, Requesting/Using unit submit

materiel requirements request to fulfill assets needed to support

an assigned exercise, operation, deployment, or contingency. The

request is submitted via an AMAL Request Letter. The draft AMAL

Request Letter should include AMAL quantities, supplemental

medical items, narcotics, Reporting Officer (RO), and Course of

Action (COA)*, as required. Unit coordinate with its internal

Chain of Command (Supply Battalion/CLR) to approve a draft AMAL

Request Letter and then send to the MEDLOGCO.

Important Note: Units must submit materiel requirements a minimum

of 45 days prior to the event, exercise, or deployment. The HSSE

Letter must include a Line Of Accounting (LOA).

Input: Warning Order/Letter of Instruction (LOI)

Output: Draft AMAL Request Letter

Document: See Chapter 1.c. for an example ―AMAL Request Letter‖

*COA does not apply to MARFORRES.

2. Review request & determine AMALs/ADAL deficiencies

Description: For pre-coordination, MEDLOGCO receive the draft

AMAL Request Letter from the unit and determines asset

availability/readiness by creating an assemblage roll-up report

in DMLSS. This report summarizes the readiness status of

multiple AMAL blocks and identifies the overall dollar

deficiency. MEDLOGCO incorporate the deficiency data into the

draft AMAL Request letter and send to the MSC/MLG.

Input: Draft AMAL Request Letter

Output: E-mail/phone call

3. Review request & verify the requesting unit rates the materiel

Description: For pre-coordination, MSC or MLG (HSSO), as

appropriate, receive the draft AMAL Request Letter and verifies

whether or not the unit rates the requested AMALs/ADAL blocks,

based on the Table of Equipment (T/E) established in TFSMS.

MSC/MLG incorporate the approval/ disapproval recommendation into

the draft AMAL Request Letter and send to the Requesting/Using

unit for refinement and submission.

Input: E-mail/phone call

Output: Health Service Support Element (HSSE) endorsement/draft

AMAL Request Letter

Class VIII Management

1-11

4. Refine and submit materiel requirements request

Description: Requesting/Using unit refine and submit AMAL

Request Letter to MEF/MARFORRES for approval.

Input: HSSE endorsement/draft AMAL Request Letter

Output: AMAL Request Letter (submitted by unit)

5. Receive materiel request

Description: MEF/MARFORRES receive the AMAL Request Letter and

review the input from Requesting/Using Unit. MEF/MARFORRES

determine whether or not to approve the request for the

AMALs/ADAL through a two-part approval process.

Input: AMAL Request Letter (submitted by unit)

6. Reject request and send back to Unit

Description: If MEF/MARFORRES deny the request provided in the

AMAL Request Letter, the MEF/MARFORRES send the letter back to

the unit with a justification for why the request was denied.

Input: Draft AMAL Request Letter

Output: Denied unit AMAL Request w/justification

7. Modify request for resubmission

Description: Requesting/Using unit receive the denied AMAL

Request and modify in accordance with the justification provided

by the MEF/MARFORRES and resubmit for approval.

Important Note: The resubmission of the Adjusted AMAL Request

letter will follow the same process steps as the original

submission.

Input: Denied unit AMAL Request w/justification

Output: Adjusted AMAL Request Letter

8. Task designated office to support

Description: If MEF/MARFORRES approve the request provided in

the AMAL Request Letter, the MEF/MARFORRES task the MSC/MLG to

prepare Class VIII materiel for release to the unit.

Input: Unit AMAL Request

Output: HSSE endorsement of AMAL Request + Unit AMAL Request

Letter

Class VIII Management

1-12

9. Receive task and prepare to provide support

Description: MSC or MLG (HSSO), as appropriate, receive the

approved/signed MEF endorsement and unit request and initiate

procedures required to prepare Class VIII materiel for release to

the unit.

Input: HSSE endorsement of AMAL Request + Unit AMAL Request

Letter

10. Notify unit of request approval

Description: MSC/MLG, as appropriate, notify the unit that the

AMAL Request Letter has been approved and provide instructions on

the unit’s requirements for the Pre-LTI process.

Output: Email/Phone call

11. Task designated office to support request

Description: MSC/MLG, as appropriate, task the MEDLOGCO to

prepare Class VIII materiel for release to the unit. This task

is provided in the form of a Pre-LTI Letter, which contains a

summary of the items (i.e., equipment and consumables) and is

approved for release.

Output: HSSE endorsement of AMAL Request + Unit AMAL Request

Letter

12. Receive notification

Description: Requesting/Using unit receive notification of

approval and instructions from the MSC/MLG required to initiate

the Pre-LTI process. Requesting unit coordinate internally to

designate a primary/alternate Reporting Officer to conduct the

Pre-LTI and a preferred date/time to conduct the Pre-LTI.

Important Note: The RO must be an Officer or SNCO designated from

the requesting unit.

Input: Email/Phone call

Output: Identified ROs, Proposed Pre-LTI date/time

Class VIII Management

1-13

13. Coordinate to schedule Joint LTI

Description: Requesting/Using unit and MEDLOGCO coordinate to

make final preparation for the Pre-LTI. This includes confirming

the date/time and discussing roles/responsibilities and

expectations for the Pre-LTI. Based on unit requirement, MEDLOGCO

generate Pre-LTI to include AMAL quantities, supplemental medical

items, LOA, RO, etc. Any remaining requirements prior to the

inventory are assigned accordingly.

Input: Designated RO, Proposed Pre-LTI date/time

Output: Pre-LTI Letter

14. Review AMALs/ADAL Status

Description: Prior to the Pre-LTI, MEDLOGCO run a Status Summary

Report in DMLSS-AM. This report provides the attainment

percentage and the dollar deficiency for a given block. The

report enables the MEDLOGCO to identify the appropriate block to

pull.

Input: Pre-LTI Letter/Schedule date

Output: Assemblage Status Summary Report (DMLSS-AM)

Document: See Chapter 1.d. for an example “Assemblage Status

Summary Report”

15. Pull AMALs/ADAL

Description: Based on the block identified from the Status

Summary Report, MEDLOGCO pull the block from the warehouse.

MEDLOGCO determine the deficiencies in the block requiring

replenishment.

Input: Assemblage Status Summary Report (DMLSS-AM)

Output: List of block deficiencies

Reference: See Chapter 1.d. for an example “Assemblage Status

Summary Report” and reference the ―Useful Reports‖ section of the

NAVMC 4000.3 for additional information.

Class VIII Management

1-14

16. Conduct Asset Review

Description: MEDLOGCO conduct an asset review to determine in-

house (on-hand) replenishment from secondary location or excess

stocks in the warehouse that can be used to increase the block’s

readiness percentage. MEDLOGCO pull shelf-life & other items to

build AMALs/ADAL. Then, MEDLOGCO adjust the deficiencies to

reflect items required for external replenishment.

Input: Block deficiencies list (DMLSS-AM, ―Replenishment

Report‖)

Output: Adjusted block deficiencies list

Reference: ―Searching for Replenishment Items‖, ―Useful

Reports‖, and ―Asset Review‖ sections in the NAVMC 4000.3.

17. Order deficiencies

Description: MEDLOGCO utilize DMLSS to order remaining

deficiencies not available in the warehouse. DMLSS sources

deficiencies from either the Prime Vendor Medical Surge

(PVM)/Prime Vendor Pharmacy (PVP) or through DLA’s Contingency

Contracts. (See Chapter 4.2. Sourcing Timeline for amplifying

information on PVM/PVP and DLA contracts). MEDLOGCO generate a

―Replenishment Report,‖ a list of items to be procured to

increase readiness, and a DUE-INs Report, a list of what is

coming in based on orders, via DMLSS.

Important Note: Orders pending in DMLSS are reflected as DUE-INs.

Once the orders are processed, the percentage readiness is

automatically adjusted in the AMALs/ADAL block. Therefore, it is

essential that MEDLOGCO accounts for planned verse actual

adjustments to block inventory to ensure they are not conducting

unnecessary inventories or reporting false attainment. An

example checklist is provided in Chapter 1.d. to facilitate

tracking of external replenishment.

Due to delivery times associated with PVM/PVP, it may take as few

as 48 hrs and up to 14 days to get the requested assets required

to bring the block up to 100%.

Input: Adjusted block deficiencies list

Output: Replenishment Report & DUE-INs Report

Reference: ―Useful Reports‖ section in NAVMC 4000.3.

Class VIII Management

1-15

Figure 8.4 Pre-LTI Process Descriptions

18. Conduct Joint LTI

Description: Once all assets are acquired to bring the block up

to the desired level of readiness, the MEDLOGCO and designated

unit RO conduct a Joint LTI to include a QA/QC of line items,

item quantity, SL3 equipment, and shelf-life assets and ensure

that Biomedical has conducted operational checks on designated

equipment. A Controlled Substance Officer is present during this

process to sign for all narcotics. Upon completion of a

satisfactory inspection, RO sign for the AMALs/ADAL and

acknowledge the percentage of readiness and standardized

configuration or most current packing list from MCSC.

Important Notes: The RO must be an Officer or SNCO designated

from the requesting unit. Additionally, narcotics/controlled

substances must be signed for by an Officer in accordance with

MANMED P-117 and OPNAVINST 3120.32C.

The Joint LTI does not apply in cases of global sourcing or for

the release of MARFORRES assets, in which case only an LTI is

performed. Per MARFORRES Force Order 6000, MARFORRES will

conduct a JLTI if the requesting unit funds MARFORRES travel.

Input: Confirmed Pre-LTI date/time, MCSC Packing List

Output: Signed AMALs/ADAL Block; Pre-LTI Packing List

19. Transfer AMALs/ADAL to unit & drop asset in records

Description: Once the RO has signed for the AMALs/ADAL, MEDLOGCO

coordinate with unit to transport asset. Upon completion,

MEDLOGCO remove the asset from the MEDLOGCO property records in

GCSS-MC (or SASSY, as applicable). Additionally, MEDLOGCO update

DMLSS-AM of all DUE-INs receipts and freeze AMALs/ADAL block at

the level at which it was transferred.

Reference: http://www.marcorsyscom.usmc.mil/sites/gcss-

mc/index.aspx; ―Transferring an Assemblage Out of Your

Organization (Loss)‖ section in NAVMC 4000.3.

Input: Signed AMALs/ADAL Block

Output: AMALs/ADAL GCSS-MC record

20. Pick-up asset in records

Description: Upon receipt of the AMALs/ADAL, Requesting/Using

unit add the asset in the unit’s property records in GCSS-MC (or

SASSY, as applicable).

Reference: http://www.marcorsyscom.usmc.mil/sites/gcss-

mc/index.aspx; ―Transferring an Assemblage into Your Organization

(Gain)‖ section in NAVMC 4000.3.

Input: AMALs/ADAL GCSS-MC record

Class VIII Management

1-16

c. Example: AMAL Request Letter (SAMPLE)

From: Commanding Officer, [Requesting Unit]

To: Commanding Officer, Medical Logistics Company, [1

st

, 2

nd

, or 3

rd

, Delete

for MFR] Supply Battalion, [1

st

, 2

nd

, 3

rd

, 4

th

] Marine Logistics Group

[Location]

Via: Commanding General, [1

st

, 2

nd

, 3

rd

] Marine Expeditionary Force

(MEF)/Marine Forces Reserve (MFR)

Commanding General, [1

st

, 2

nd

, 3

rd

, 4

th

] Marine Logistics Group or Major

Subordinate Command, G-3 (HSSE)

Subj: REQUEST FOR AMALs/ADAL IN SUPPORT OF FIELD OPERATIONS.

1. It is requested that the following AMALs/ADAL, pharmaceutical, and

consumable list be provided in support of Field Operations.

NOMENCLATURE QTY

[Block, Designate AMAL/ADAL] [xxx]

EXAMPLE: 699 AMAL BLOCK 01

2. The following additional information is provided

a. Responsible Officer (RO): Rank, Last, First, Middle Initial. xxx-xx-

last four of SSN] EXAMPLE: LT John , Doe xxx-xx- [

b. Date of inventory/ LTI: [dd_MMM-yyyy] EXAMPLE: 29 APR 2010

c. Date of pick up: [dd_MMM-yyyy] EXAMPLE: 29 APR 2010

d. Estimated date of return: [dd_MMM-yyyy] EXAMPLE: 15 MAY 2010

e. RA Job Order Number (JON): [JON associated with line of accounting to

fund request]

f. Reporting Unit (RUC): [xxxxx] EXAMPLE: 11330

3. Point of contact for this request is, [Rank, Last, First, Middle

Initial., Phone, Email] EXAMPLE: HM3 Vollstedt, Ross @(760) 830 5552

4. An advance copy of this request was sent to CO, Medical Logistics

Company, 1

st

Supply Battalion, 1

st

Marine Logistics Group on 13 APR 2010.

J. A. SMITH

Class VIII Management

1-17

d. Assemblage Status Summary Report (SAMPLE)

Class VIII Management

1-18

Post-LTI Procedures

Post-LTI procedures are performed after the return of the using unit

in order to ensure proper configuration (according to MCSC standards),

validate that all equipment is accounted for and in good working

order, and determine preliminary replenishment requirements.

It is important that all AMALs/ADAL are returned in the same

configuration in which the equipment was issued (i.e., cleaned and in

the standard configuration as Pre-LTI).

Participants in this phase are:

Marine Logistics Group (MLG)

Medical Logistics Company (MEDLOGCO)

Supported unit

Systems in this phase are (See Chapter 9 for Systems Descriptions):

Defense Medical Logistics Standard Support—Assemblage Management

Module (DMLSS-AM)

Global Combat Support System-Marine Corps (GCSS-MC)

Standard Accounting, Budgeting, and Reporting System (SABRS)

Class VIII Management

1-19

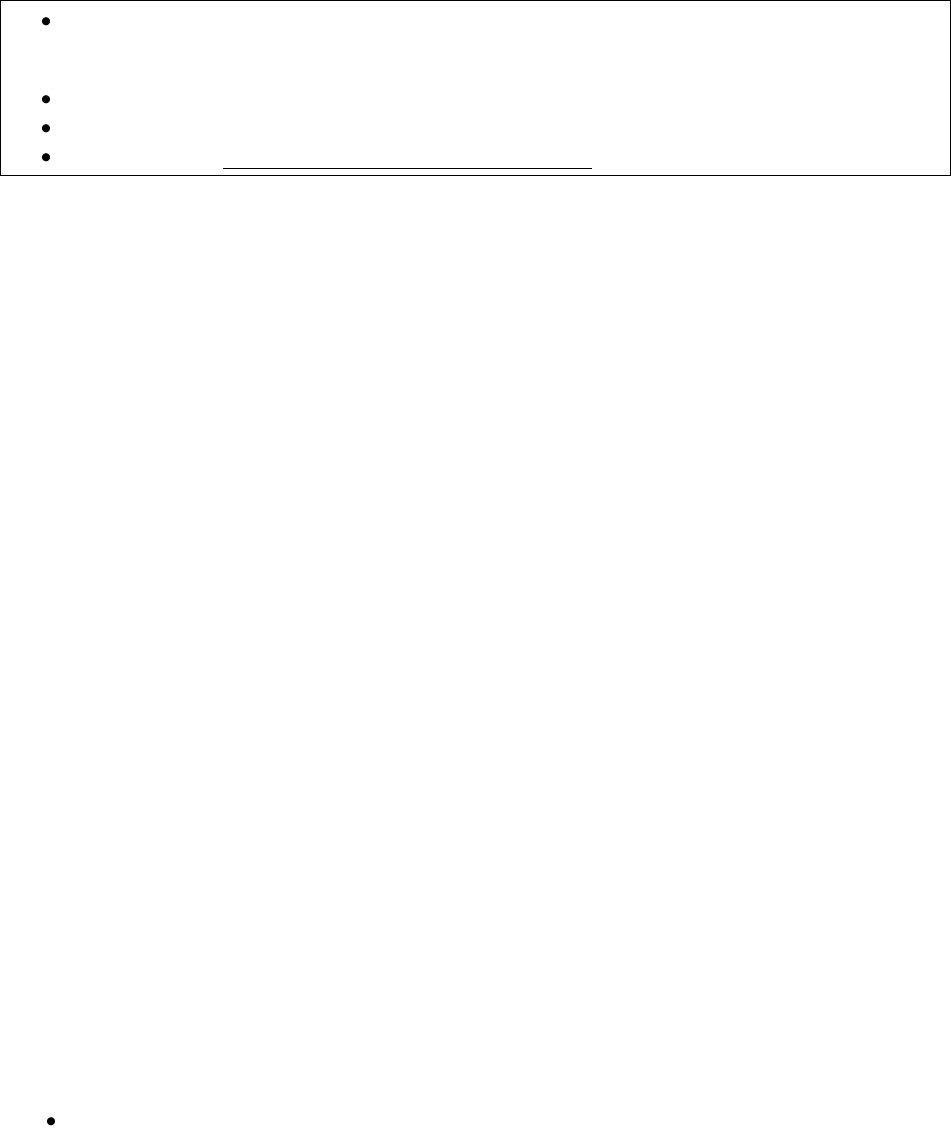

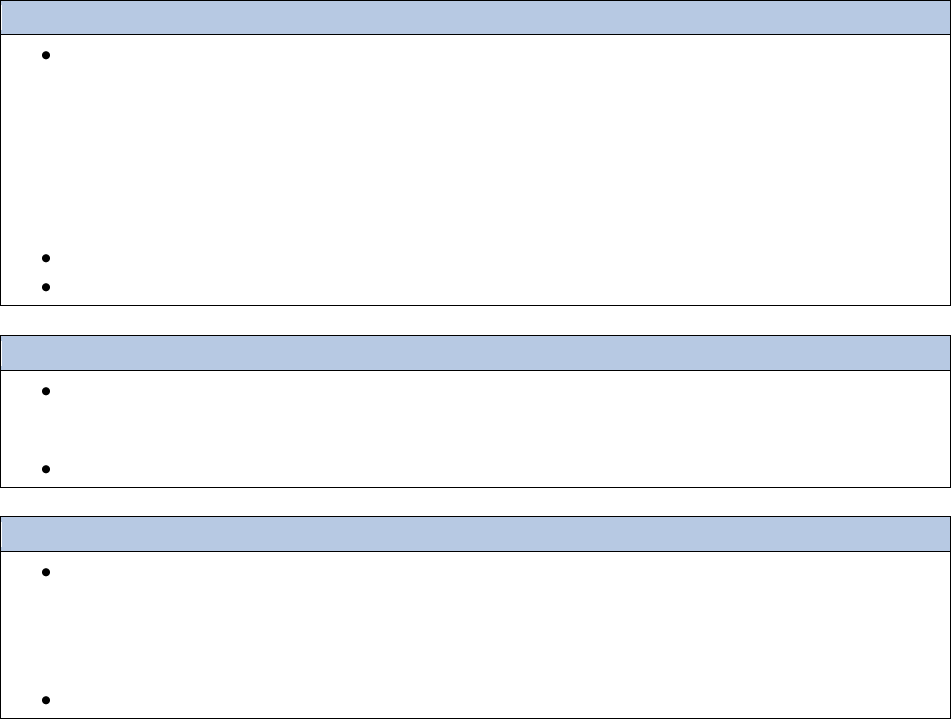

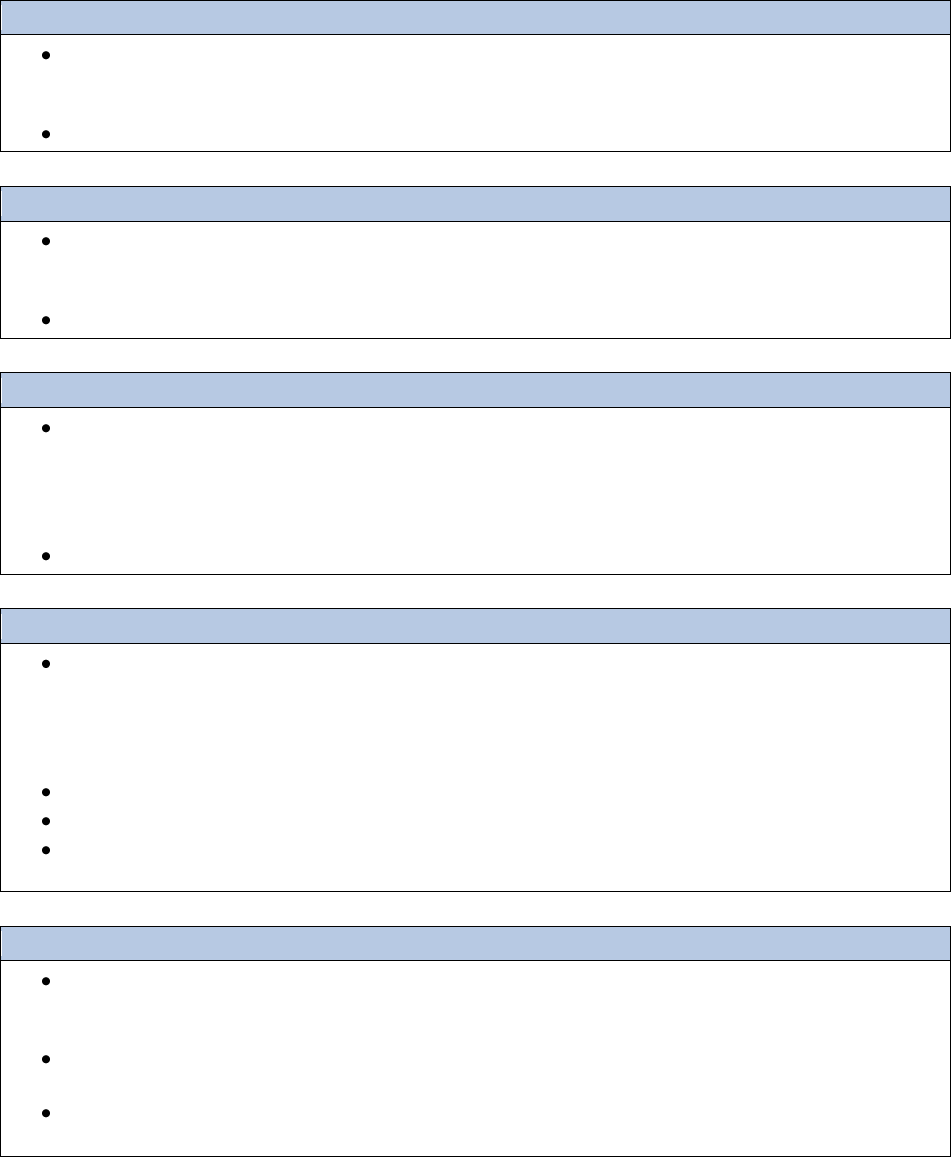

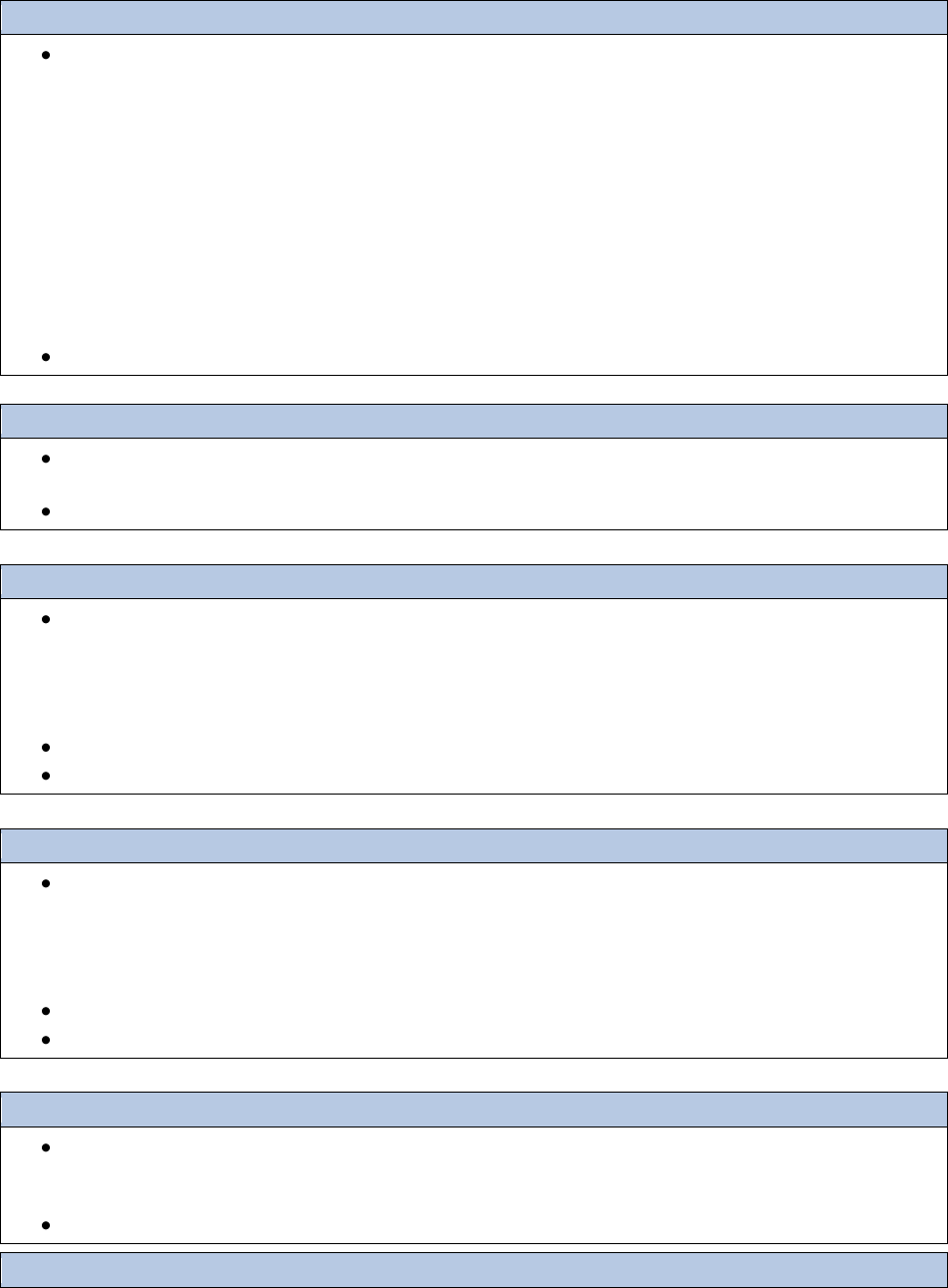

a. Process Map

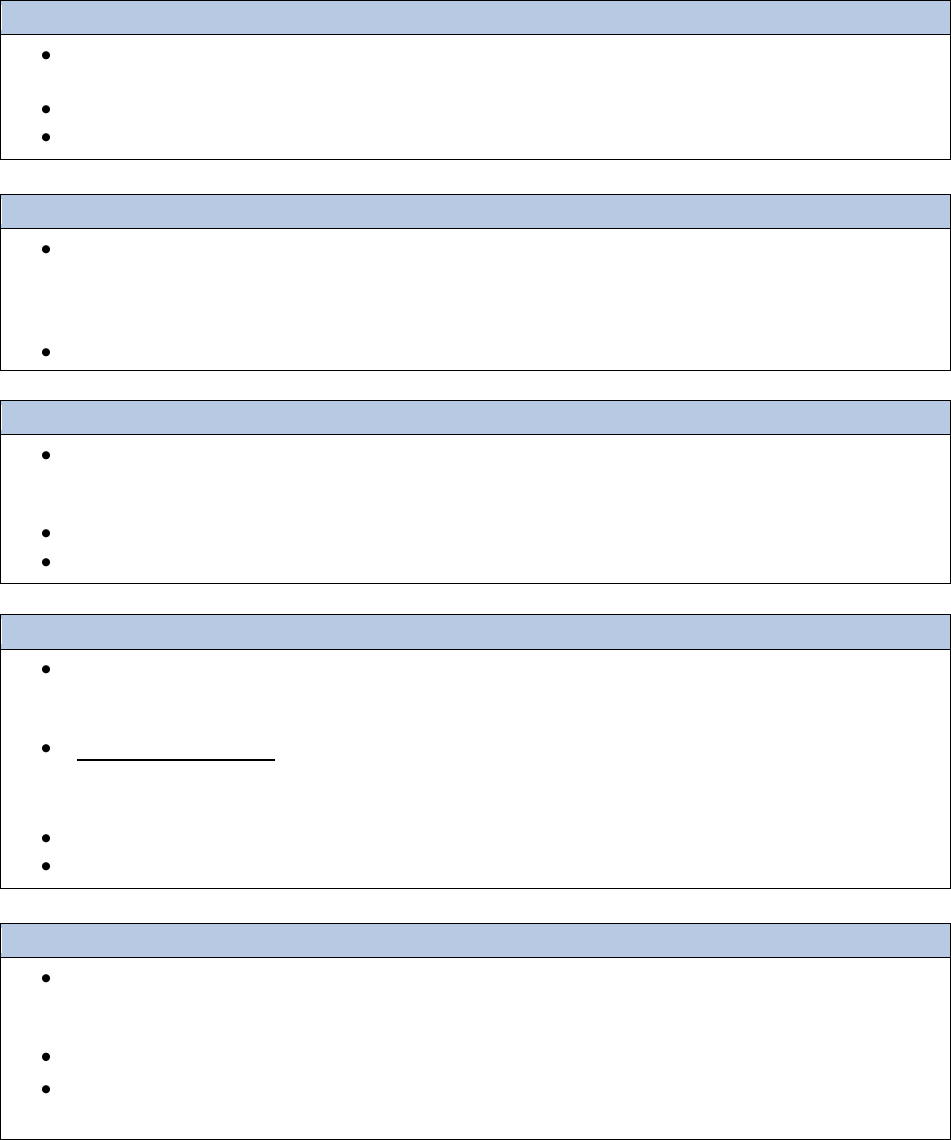

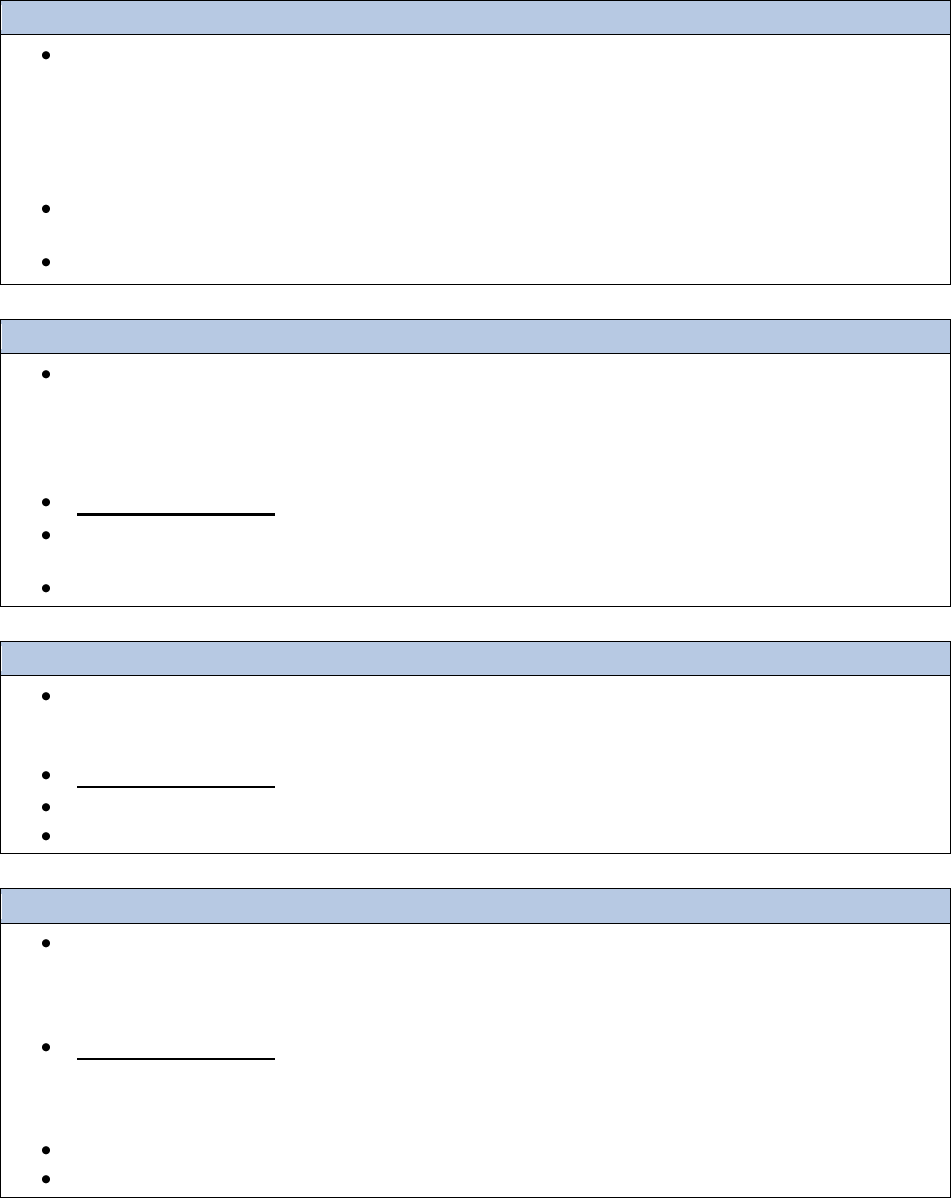

Figure 8.5 Post-LTI Process

Post-LTI Procedures

Unit

(Supported)

MEDLOGCO

MLG

(Comptroller)

Review cost

and prepare

to allocate

funds*

System

Order items to

replenish

stocks

End

* These steps do not apply

to MARFORRES

DMLSS-

AM

Create and

submit cost

for consumed/

broken items*

Conduct Joint

LTI

Review

AMALs/ADAL

Status

Coordinate to

schedule Joint

LTI

Conduct Joint

LTI

Charge unit’s

line of

accounting*

Return from

exercise,

operation,

deployment, or

contingency

Start

SABRS

Coordinate to

schedule Joint

LTI

DMLSS-

AM

Review cost

for assets

used/ items

needing to be

reconstituted*

MARFORRES

DRAFT

DMLSS-

AM

GCSS-

MC

Drop asset in

records

Pick-up asset

in records

System

Key:

Process

Step

Document

Previous

Phase

Next

Phase

Class VIII Management

1-20

b. Process Step Descriptions

1. Return from exercise, operation, deployment, or contingency

Description: Supported unit return from exercise, operation,

deployment, or contingency and report to MEDLOGCO no more than

one week following return to initiate coordination for a Post-

LTI. Supported unit designate a primary/alternate Reporting

Officer to conduct the Post-LTI and a preferred date/time to

conduct the Post-LTI. If AMALs are not returned in a timely

fashion, units may be charged for the total cost of the AMAL.

Important Note: The RO must be an Officer or SNCO designated from

the requesting unit. The RO must be the same for both Pre- and

Post-LTI.

Output: Designated ROs, Proposed Post-LTI date/time

2. Coordinate to schedule Joint LTI

Description: Unit and MEDLOGCO coordinate to make final

preparation or the Post-LTI. This includes confirming the

date/time and discussing roles/responsibilities and expectations

for the Joint LTI.

Input: Proposed Post-LTI date/time

Output: Confirmed Post-LTI date/time

3. Conduct Joint LTI

Description: MEDLOGCO and designated unit RO conduct a Joint LTI

to include; a QA/QC of line items, item quantity, SL3 equipment,

shelf-life assets, and ensure that Biomedical has conducted

operational checks on designated equipment. A Controlled

Substance Officer is present during this process to sign for all

narcotics. Upon completion of a satisfactory inspection,

MEDLOGCO sign for the AMALs/ADAL and acknowledge the percentage

of readiness.

Important Notes: The RO must be an Officer or SNCO designated

from the requesting unit. Additionally, narcotics/controlled

substances must be signed for by an Officer in accordance with

MANMED P-117 and OPNAVINST 3120.32C.

The Joint LTI does not apply in cases of Global Sourcing or for

the release of MARFORRES assets, in which case only an LTI is

performed. Per MARFORRES Force Order 6000, MARFORRES will

conduct a JLTI if the requesting unit funds MARFORRES travel.

Input: Confirmed Post-LTI date/time, Pre-LTI Packing List

Class VIII Management

1-21

4. Review AMALs/ADAL Status

Description: MEDLOGCO determine items needing replenishment

(broken/consumed) and update in DMLSS. Then MEDLOGCO run a

Status Summary Report in DMLSS and obtain the attainment

percentage and the dollar deficiency for the returned block. The

report enables the MEDLOGCO to identify the line items and

equipment to order to bring the block up to desired readiness.

Output: Status Summary Report + Supplemental SL3 or Components

Report

Reference: ―Useful Reports‖ section in NAVMC 4000.3.

5. Create and submit cost for consumed/broken items*

Description: MEDLOGCO create a Reconciliation Letter, which

includes validation of the Pre-LTI Packing List, a summary of the

items the unit signed for, and the items that were returned.

MEDLOGCO (HSSO) send the Pre/Post-LTI Letter to the Supported

Unit and the MSC/MLG Comptroller.

Important Note: This does not apply to MARFORRES.

Input: Status Summary Report + Supplemental SL3 or Components

Report

Output: Reconciliation Letter

6. Review cost for assets used/ items needing to be reconstituted*

Description: MSC/MLG (Comptroller) receive the Reconciliation

Letter and review the cost associated with consumed/broken

assets.

Important Note: This does not apply to MARFORRES.

Input: Reconciliation Letter

Output: Replenishment Cost

7. Charge unit’s line of accounting*

Description: MSC/MLG (Comptroller) charge the Line of Accounting

(LOA) provided by the requesting unit in the AMAL Request Letter

submitted during the Pre-LTI process in accordance with local

policy (see Chapter 1).

Important Note: This does not apply to MARFORRES.

If a unit’s deployment spans over two Fiscal Years (FYs) then the

requiring unit is required to provide an updated Line of

Accounting (LOA) to the MEDLOGCO.

Input: Replenishment Cost

Output: LOA Charge

Class VIII Management

1-22

8. Review cost and prepare to allocate funds*

Description: Supported unit receive the Reconciliation Letter,

review the cost associated with consumed/broken assets, and

prepare for funds to be allocated.

Important Note: This does not apply to MARFORRES.

Input: Status Summary Report

Output: Reconciliation Letter

9. Drop asset in records

Description: Upon review of the charges, supported unit remove

the asset from its property records by TAMCN in GCSS-MC.

Reference: http://www.marcorsyscom.usmc.mil/sites/gcss-

mc/index.aspx; ―Transferring an Assemblage Out of Your

Organization (Loss)‖, NAVMC 4000.3.

Input: Reconciliation Letter

Output: AMALs/ADAL GCSS-MC record

10. Pick-up asset in records

Description: MEDLOGCO add the asset in the unit’s property

records by TAMCN in GCSS-MC.

Reference: http://www.marcorsyscom.usmc.mil/sites/gcss-

mc/index.aspx; ―Transferring an Assemblage into Your Organization

(Gain)‖, NAVMC 4000.3.

Input: AMALs/ADAL GCSS-MC record

Class VIII Management

1-23

Figure 8.6 Post-LTI Process Descriptions

c. Exceptions

There are instances when a unit returning from an operation will leave

the medical materiel, which is signed for, in-theater for other units

to fall-in on. In this case, no Post-LTI will be performed by the

departing unit, but it is recommended that the fall-in unit conduct a

Post-/Relief LTI in order to account for all equipment and materiel.

The fall-in unit will follow the Pre-LTI procedures for routing an

AMAL Request Letter up the Chain of Command. The AMAL Request Letter

will be used to report the materiel as a combat loss.

Once the MEFs sign the AMAL Request Letter and provide it to the

MSC/MLG and the MEDLOGCO, the MEDLOGCO will drop the AMALs/ADAL in

DMLSS and update the on-hand quantities in GCSS-MC. Then the MEDLOGCO

will create a Combat Loss Letter summarizing the assets for which the

unit signed. A Responsible Officer (RO), an Officer, or SNCO

designated by the unit will report to the MEDLOGCO to sign the Combat

Loss Letter. The signed letter will be provided to the comptroller at

the MLG to receive funding to replenish the stocks left in-theater.

The MEDLOGCO is responsible for replenishing the stocks after receipt

of funding.

3. Proper Care and Storage of Pharmaceuticals

All pharmaceuticals should be stored in a temperature-controlled

environment, in accordance with manufacturer guidance. Failure to

store pharmaceuticals at appropriate temperatures in combination with

regular monitoring temperature and humidity (T/H) monitoring may

result in advanced deterioration or reduced pharmaceutical

11. Order items to replenish stocks

Description: MEDLOGCO utilize DMLSS to order replenishment

stocks to bring the asset to the required level of readiness.

DMLSS sources deficiencies from either the PVM/PVP or DLA’s

Contingency Contracts. (See Chapter 4, Sourcing Timeline for

amplifying information on PVM/PVP and DLA contracts). MEDLOGCO

generate a Replenishment Report, a list of items to be procured

to increase readiness, and a DUE-INs Report, a list of what is

coming in based off order, via DMLSS.

Important Note: Orders pending in DMLSS are reflected as DUE-INs.

Once the orders are processed, the percentage readiness is

automatically adjusted in the AMALs/ADAL block. Therefore, it is

essential that MEDLOGCO accounts for planned verse actual

adjustments to block inventory to ensure they are not conducting

unnecessary inventories or reporting false attainment. Due to

delivery times associated with PVM/PVP, it may take as few as 48

hrs and up to 14 days to get the requested assets.

Output: Replenishment Report & DUE-INs Report

Reference: ―Search for Replenishment Items‖, NAVMC 4000.3.

Class VIII Management

1-24

effectiveness. Proper storage in a temperature-controlled storage

facility will ensure the shelf-life of all medical and dental

pharmaceuticals, as well as limit loss of inventory and adverse

clinical effects caused by improper storage. In order to ensure that

proper storage standards are met, all USMC units storing

pharmaceuticals will provide the following:

a. A temperature and humidity (T/H) controlled monitoring program to

ensure that all stored pharmaceuticals meet the manufacturer

requirements.

b. Continuous or periodical monitoring of stored equipment and

consumables. If monitored periodically, consumables/equipment

will be recorded twice within a 24-hour period, and all readings

will be posted and available for inspections. Continuous

monitoring will be conducted in accordance with an approved USMC

monitoring system. Use of a commercial alarm to indicate a

single event and/or record detailed time and temperature history

is recommended.

Any pharmaceuticals that have been exposed in an uncontrolled

environment for 72 hours will be considered unserviceable. The lot

number will be recorded and pulled from the shelves, and if the

pharmaceuticals have a total value in excess of $1000, they may be

submitted to the FDA for acceptance into the Shelf Life Extension

Program in accordance with BUMED 6710.62A. Pharmaceuticals that do

not meet the standards for entry into the Shelf Life Extension Program

will be prepared for disposal.

4. CBRN Materiel Management

CBRN skin decontamination kits are Class VIII assets are centrally

managed with all Marine Corps non-medical CBRN equipment. The WRM

requirements for CBRN skin decontamination kits are calculated and

managed using the same procedures as Class II materiel and are

procured by MCSC through the Warfighting PEB.

In addition to the skin decontamination kits, MEFs maintain all other

Class VIII CBRN materiel as individual line items, rather than as

configured AMALs, at the quantities required to support a force

employment package. MEFs shall determine an appropriate personnel

requirement in accordance with the minimum number of on-hand CBRN

equipment they maintain. This will be the quantiiy held on-hand at the

MEDLOGCO vice the total AAO. This number is updated on an annual

basis in order to reflect changes in MEF-held CBRN equipment levels.

MEFs source their Class VIII CBRN requirements through a combination

of in-stores assets (on-hand) or through the use of existing DLA-

managed contingency contracts (remaining AAO). MEDLOGs are required to

utilize DLA contracts for tiered resupply of remaining materiel

requirements. Additionally, MEFs are required to develop and implement

an incremental procurement and replenishment program in order to

ensure shelf life dating for MEF-held CBRN materiel is spread across

Class VIII Management

1-25

multiple manufacturer production lots. MEDLOGCOs shall follow

BUMEDISNT 6710.62 and DODI 6430.02 on DoD/Food and Drug Administration

(FDA) Shelf Life Extension Program (SLEP) materiel and shall enter all

qualified NSN in the SLEP database located at:

https://slep.dmsbfda.army.mil/portal/page/portal/SLEP_PAGE_GRP/SLEP_HO

ME_NEW.

Marine Corps Logistics Command (MCLC) is responsible for managing

Class VIII CBRN requirements to support follow-on forces and

MARFORRES, as well as managing all USMC Class VIII (SLEP) materiel.

CBRN materiel requirements managed by MCLC are sourced through a

combination of contingency contracts, DoD/FDA SLEP materiel, or in-

stores inventory. Any MEF-held Class VIII CBRN materiel that expires

and meets the criteria for testing in the DoD/FDA SLEP should be

transferred to MCLC and held as SLEP materiel.

5. Biomedical Equipment Management

Biomedical Equipment Technicians (BMETs) are taught the basic theory

and concepts of different classes of medical equipment at the DoD

Biomedical Equipment Technician (BMET) School and are capable of

performing level II maintenance on the classes of equipment held

within the Marine Corps inventory. Since some equipment is a product

of new technology, BMETs should apply their training to new equipment

with use of service and operator manuals.

Training in medical equipment technology that is not provided by the

DoD BMET School will be funded by MCSC. BMETs, in turn, will be

required to train other BMETs in the MEDLOG on new equipment in order

to sustain technical knowledge gained from initial training.

Additional training requested after the initial training class will be

funded by the requesting command.

The frequency of scheduled medical equipment maintenance should comply

with the manufacturer’s requirements or frequency established by

NAVMEDLOGCOM. The Biomedical Engineering Division (BIOMED) is

required to use the DMLSS Device Code and Life Expectancy Table for

assigning risk levels and maintenance frequency.

For additional information, please see the NAVMEDLOGCOM Biomedical

Equipment Division Support website at

https://gov_only.nmlc.med.navy.mil/.

Class VIII Management

2-1

NAVMC 4000.2

Class VIII Management

Requirements Determination

Chapter 2

Class VIII Management

2-3

A. Requirements Determination

Requirements Determination, in conjunction with the Selection Criteria

function described in the previous chapter, parallels the Plan Health

Service Support phase of the NAVMEDLOGCOM process for determining

medical support requirements.

The Marine Corps has two distinct phases for determining Class VIII

materiel requirements. The first phase is to establish initial issue

(15 DOS) requirements as a part of the unit T/E listed in TFSMS. The

AMALs/ADAL types and quantities in the T/E comprise the unit’s basic

allowance, which the MEDLOGCO will hold and maintain. These

AMALs/ADAL also undergo routine reviews to ensure the type and

quantity of materiel is in accordance with changing mission objectives

or force structure.

1. Requirements Determination — Initial Issue

Participants in this phase are:

Deputy Commandant Combat Development & Integration (DC CD&I)

Combat Development Directorate (CDD)/Logistics Integration

Division (LID)

Deputy Commandant Combat Development & Integration (DC CD&I)

Total Force Structure Division (TFSD)

Marine Corps Systems Command (MCSC)

Marine Forces (MARFOR)

Marine Expeditionary Forces (MEFs)

Marine Forces Reserve (MARFORRES)

Using unit

Additional participants that contribute to this phase include:

Marine Corps Warfighting Laboratory (MCWL)

Training & Education Command (TECOM)

MCWL coordinates with DC CD&I to support pre-phase efforts in

informing DC CD&I on any projects researching developmental

equipment/assets that may be used to fill a gap in requirements.

Additionally, MCWL supports post-phase efforts in conducting testing

and evaluation on requirements to document justification for

prioritization of requirements.

TECOM coordinates with DC CD&I to support the post-phase effort in

identifying the training requirements associated with permanent

programs.

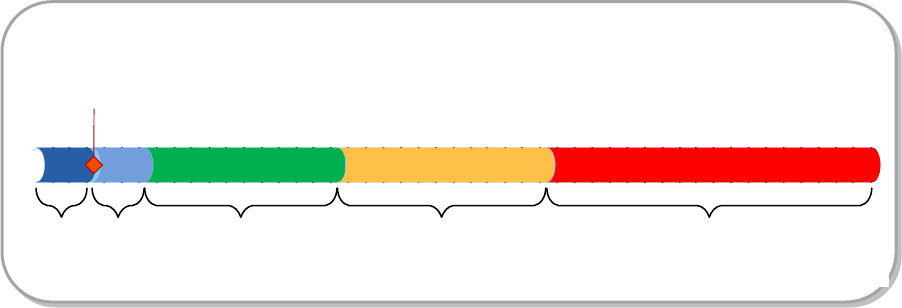

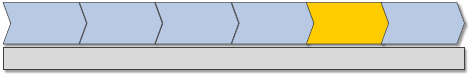

Systems in this phase are (See Chapter 9 for Systems Descriptions):

Selection

Criteria

Requirements

Determination

Sourcing Positioning Acquisition Distribution

Management

Class VIII Management

2-4

Total Force Structure Management System (TFSMS)

Global Combat Support System-Marine Corps (GCSS-MC)

Program Budgeting Documentation Database (PBDD)

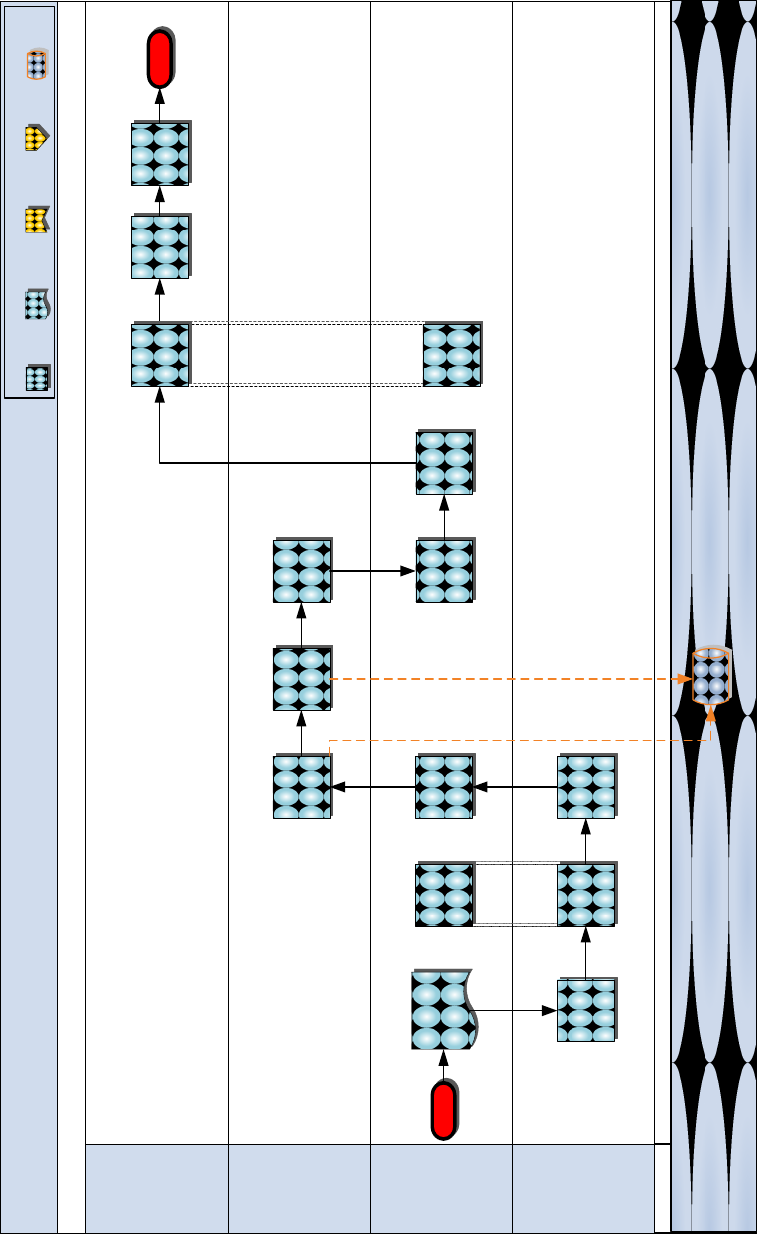

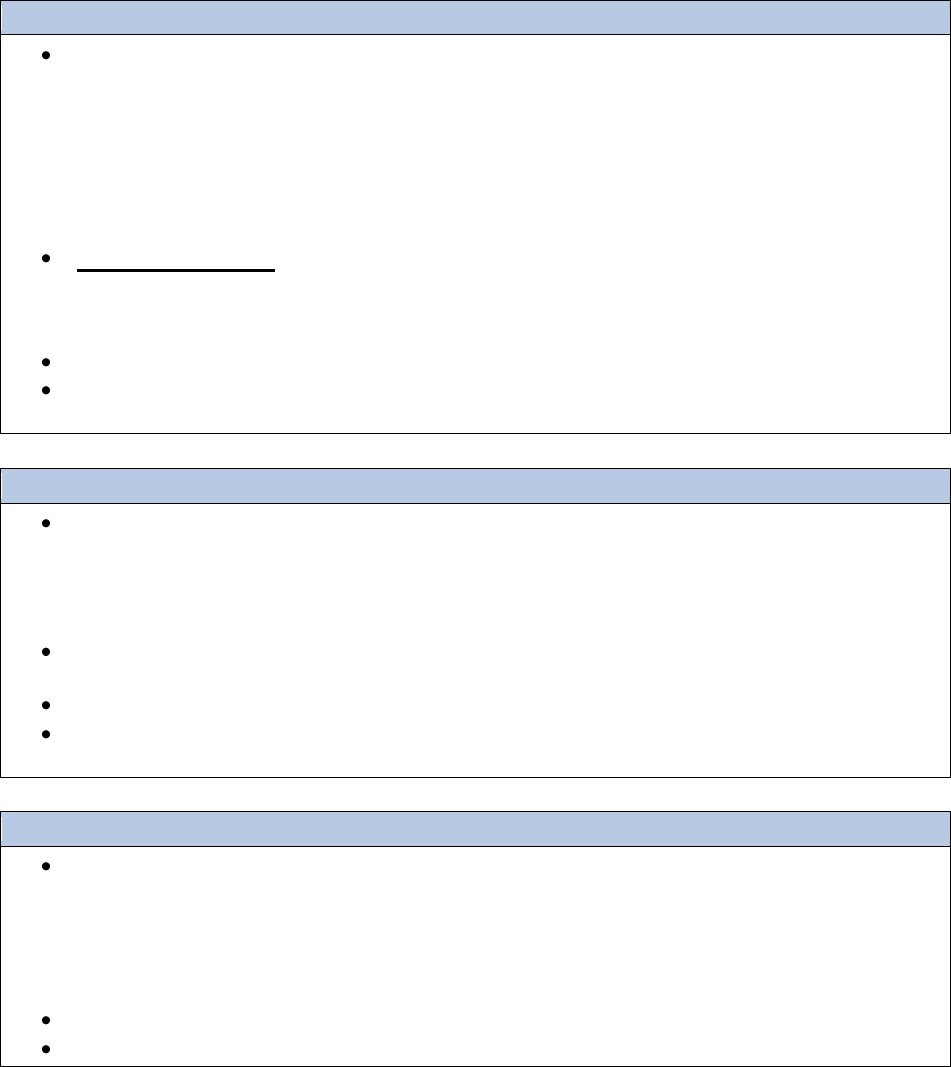

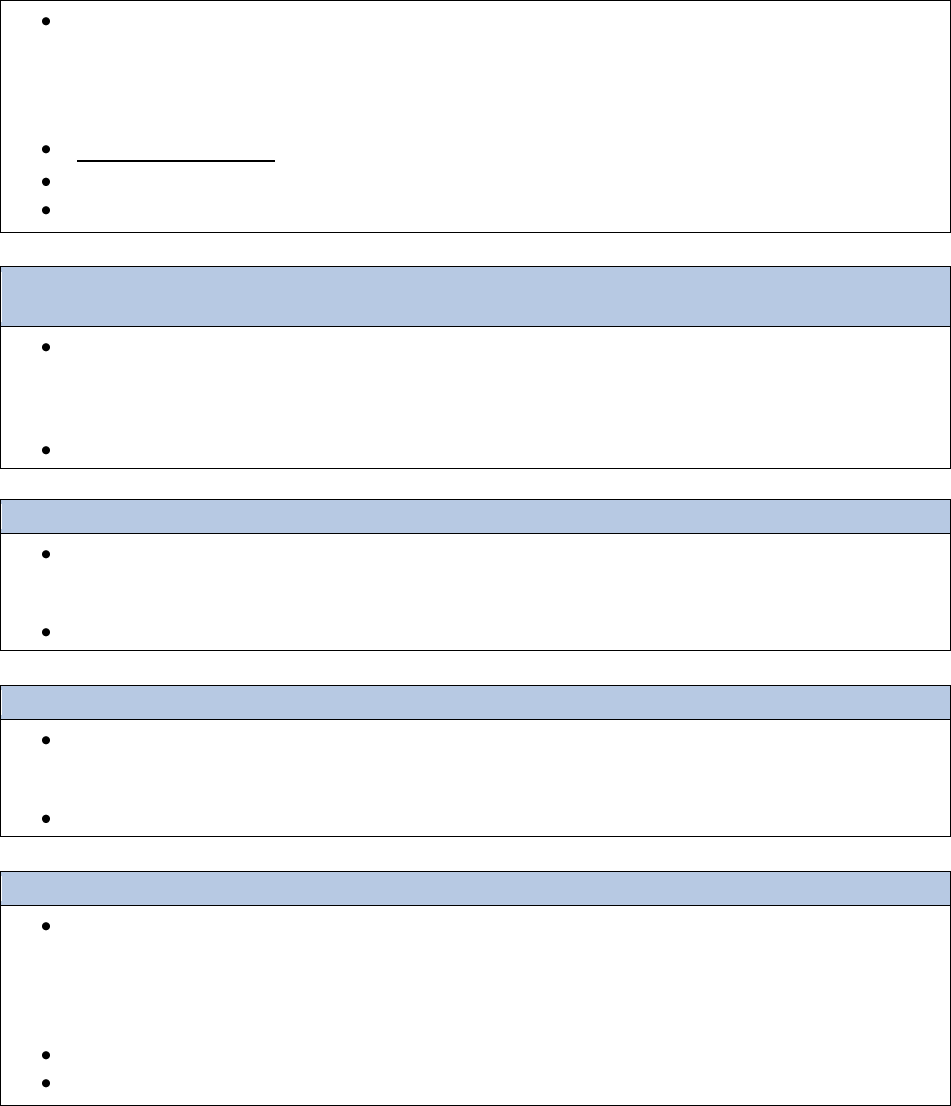

a. Process Map

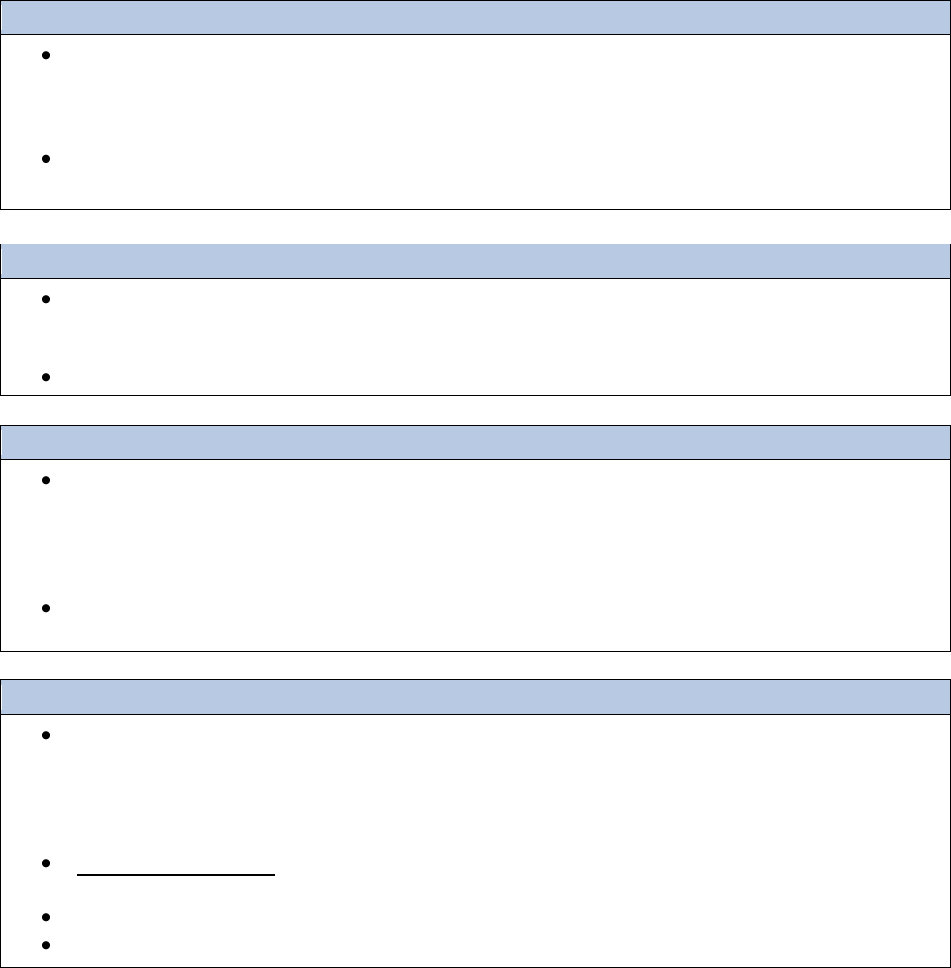

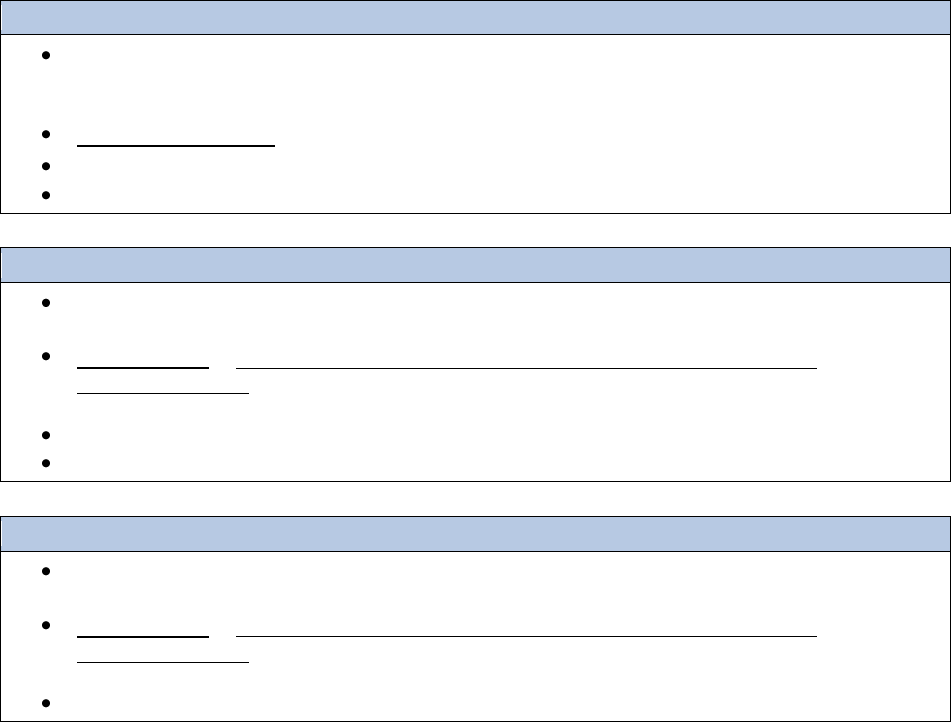

Figure 8.10 Requirements Determination—AAO Initial Issue Process

Requirements Determination – Initial Issue (AAO)

MCSC

DC CD&I

(TFSD)

Unit

MEF/

MARFORRES

(MLG)

MARFOR

DC CD&I

(CDD/LID)

System

Start

Staff

requirement

internally for

CDD approval

Inputs

requirements

into the

system of

record

Coordinate for

AAO

programming/

budgeting

Coordinate for

AAO

programming/

budgeting

View

modifications

to the AAO

View

modifications

to the AAO

TFSMS

Create &

submit

TOECR

Review &

approve

TOECR

View

modifications

to the AAO

View

modifications

to the AAO

Submit

initiative for

Class VIII

funding

Advocate for

Class VIII

funding

Receive

funding &

procure Initial

Issue assets

Field Class

VIII Initial

Issue

Receive Initial

Issue

Acknowledge

receipt of

Initial Issue

PBDD

GCSS-

MC

TFSMS

DRAFT

Determine

requirement

for initial issue

(AAO T/E)

Send

approved

SON/UUNS

End

TFSMS

View initial

Issue has

been received

Validate initial

Issue has

been received

Previous

Phase

Next

Phase

Process

Step

Document

Key:

System

Class VIII Management

2-5

b. Process Step Descriptions

1. Determine requirement for initial issue (AAO T/E)

Description: DC CD&I (CDD/LID) determine a new requirement for

initial issue (AAO T/E, 15 DOS). Based on this requirement, LID

create a Statement of Need (SON) or an Urgent Universal Needs

Statement (UUNS) to substantiate the requirement. The SON/UUNS

contain the asset’s concept of employment, characteristics, and

Approved Acquisition Objective (AAO) broken down by MEFs,

MARFORRES, Maritime Prepositioning Ships (MPS), MARSOC, Support

Establishment, and MARFORs.

Important Note: The pharmacy is not included in the initial issue

(AAO T/E, 15 DOS) process. It is the responsibility of the

MEDLOGCOs to procure through the Prime Vendor Pharmacy (PVP) or

DLA Contingency Contracts.

Input: JCIDS/EFDS Program of Records

Output: SON/UUNS

2. Staff requirement internally for CDD approval

Description: DC CD&I (CDD/LID) staff the SON/UUNS internally

through CDD to get approval for the modification to the (AAO

T/E). Approval is granted via a CDD Letter of Approval.

Input: SON/UUNS

Output: CDD Letter of Approval

3. Create and submit TOECR

Description: DC CD&I (CDD/LID) create and submit a Table of

Organization and Equipment Change Request (TOECR) to the Total

Force Structure Management Structure (TFSMS). After inputting

the TOECR into TFSMS, CDD/LID should submit the TOECR to DC CD&I

(TFSD) for review and approval.

Input: CDD Letter of Approval

Output: TOECR

4. Review and approve TOECR

Description: DC CD&I (CDD/LID) coordinate with DC CD&I (TFSD) to

determine the impacts on the Marine Corps Approved Acquisition

Objective (AAO). Upon successful completion of analysis, CDD

endorse and LID forward to TFSD for action.

Input: TOECR

Output: CDD Endorsement/Approved TOECR

Class VIII Management

2-6

5. Input requirements into the system of record

Description: DC CD&I (TFSD) input new initial issue (15 DOS)

requirements (T/E), in accordance with the approved TOECR, into

the system of record, TFSMS. Each new requirement is associated

with a Unit Identification Code (UIC).

Input: Approved TOECR

Input: Adjust T/E

6. View modifications to the AAO

Description: MCSC, MARFOR, MEF/MARFORRES (MLG), and the supported

unit view adjustments to the T/E associated with their UIC in

TFSMS.

Input: Adjust T/E

7. Send approved SON/UUNS

Description: DC CD&I (CDD/LID) send the approved SON/UUNS to

MCSC to provide MCSC with a confirmation that the AAO has been

loaded and enable MCSC to initiate procurement/budgeting.

Output: SON/UUNS

8. Coordinate for AAO programming/budgeting

Description: DC CD&I (CDD/LID) and MCSC (PM-CSE) collaborate to

generate a justification and support documentation to establish a

Class VIII initial issue (15 DOS) initiative for

programming/budgeting.

Input: SON/UUNS

Output: Initial Issue Funding Line

9. Submit initiative for Class VIII funding

Description: MCSC (PM-CSE) submit a request for Class VIII

initial issue (15 DOS) funding in the PBDD. The initiative

articulates the unfunded requirements, identifies the pre-

existing budget-line/funding profile which supports the

requirements, and justifies the need for the initial issue (15

DOS) type and quantity.

Input: Initial Issue Funding Line

Output: PBDD Initial Issue Entry

Class VIII Management

2-7

10. Advocate for Class VIII funding

Description: DC CD&I (CDD/LID) serve as the Class VIII program

advocate and articulate the value/benefit of new program

resources as outlined in the Initial Issue Initiative, in order

to help ensure that Class VIII Initial Issue (15 DOS)

requirements receive funding in the POM Process (See NAVMC

4000.1, Chapter 8: Acquisition for more information on the POM

Process). Class VIII requirements are briefed to the Warfighting

Program Evaluation Board (WIPEB).

Input: PBDD Initial Issue Entry

Output: WIPEB Submission

11. Receive funding and procure initial issue assets

Description: At the completion of the POM cycle, MCSC (PM-CSE)

receive Class VIII funding and procure initial issue (15 DOS)

assets.

Input: Class VIII funding

Output: Initial Issue

12. Field Class VIII initial issue

Description: Once MCSC (PM-CSE) receive the Initial Issue (15

DOS) assets from the procurement source, MCSC (PM-CSE) field the

assets to the designated MEF/MARFORRES (MLG).

Output: Initial Issue

13. Receive initial issue

Description: MEF/MARFORRES (MLG) receive initial issue (15 DOS)

from MCSC (PM-CSE) and incorporate into the Class VIII inventory.

Input: Initial issue

14. Acknowledge receipt of initial issue

Description: MEF/MARFORRES (MLG) add assets to Class VIII

inventory by updating the associated records in GCSS-MC (or

SASSY, as applicable). Upon completion, compare GCSS-MC records

to TFSMS and officially acknowledge receipt of initial issue (15

DOS) in TFSMS by updating the on-hand quantity for each

respective Unit Identification Code (UIC).

Output: Updated GCSS-MC record, Updated TFSMS On-hand quantity

Reference: http://www.marcorsyscom.usmc.mil/sites/gcss-

mc/index.aspx

15. Validate initial issue has been received

Class VIII Management

2-8

Figure 8.11 Requirements Determination—AAO Initial Issue Activities

Process Descriptions

It is important to note that modifications may be made to the basic

allowance by the unit to gain an additional Warfighting capability

deemed critical to operating forces for combat or contingency

operations. After they receive MEF Commander approval, units may

recommend substitutions or additions to their AMALs/ADAL T/E through

the Urgent Needs Process (UNP). Details regarding this process can be

referenced in MCO 3900.17, the Marine Corps Urgent Needs Process (UNP)

and the Urgent Universal Needs Statement (UUNS) or at

https://www.mccdc.usmc.mil.

2. Requirements Determination — Surge

There are two components that go into the development of surge

requirements for Class VIII materiel: Casualty Estimations (CASEST)

and Patient Streams.

The CASEST is a service requirement to determine the number of

casualties that are estimated in accordance with a given OPLAN. This

is an internal Marine Corps process comprised of collaboration between

PP&O (PLN) and I&L (LPC). As depicted in the Surge Requirement

process map (Section A.2.a.), LPC will request PLN’s support to

determine CASEST. In this process, PLN will review the numbered

OPLANs and derive an estimated number of casualties based on the

environment, duration, and intensity pertaining to the OPLAN. PLN and

LPC will establish CASEST based on two combat phases, three levels of

intensity, and other casualties.

Two phases of combat:

Assault (1st 30 days of combat)

Sustainment (Every subsequent 30 day period)

Three intensities of combat:

Low Intensity Conflict (LIC): Political-military confrontation

between contending states or groups below conventional war and

above the routine, peaceful competition among states. It

frequently involves protracted struggles of competing principles

and ideologies. LIC ranges from subversion to the use of means

employing political, economic, informational, and military

instruments to include irregular warfare scenarios. LICs are

Description: DC CD&I (CDD/LID) validate that initial issue (15

DOS) has been received and input into TFSMS by ensuring that on-

hand quantities for each respective UIC are appropriated updated.

Input: Updated TFSMS On-hand quantity

Output: Validated TFSMS On-hand quantity

Reference: https//:tfsms.mccdc.usmc.mil

Class VIII Management

2-9

often localized, generally in the third-world, but contained

regional and global security implications.

Medium Intensity Conflict (MIC): A Medium Intensity Conflict is

characterized by the protracted employment of regular armed

forces in combat as a major manifestation of power by the threat

and responding nations, and the designation of military

objectives to achieve political and economic goals. It may

include some or all of the techniques and characteristics of low

intensity conflict.

High Intensity Conflict (HIC): The relatively unconstrained use

of power by one or more nations to gain or protect territory and

interests that directly affects the survival of the nation. The

form of conflict is characterized by extreme levels of violence.

The employment of the full range of military force sustained by

the preponderance of other national resources to achieve military

and political victory is the primary use of nuclear weapons and

may include some or all of the characteristics of LIC and MIC.

LPC will provide these estimates to the Naval Health Research Center

(NHRC) for the development of patient streams. NHRC will divide the

casualty estimations into one of five sub-categories:

Wound in Action (WIA): A casualty category applicable to a

hostile casualty, other than the victim of a terrorist activity,

who has incurred an injury due to an external agent or cause. The

term encompasses all kinds of wounds and other injuries incurred

in action, whether there is a piercing of the body, as in a

penetration or perforated wound, or none, as in the contused

wound. These include fractures, burns, blast concussions, all

effects of biological and chemical warfare agents, and the

effects of an exposure to ionizing radiation or any other

destructive weapon or agent. The hostile casualty’s status may be

categorized as ―very seriously ill or injured,‖ ―seriously ill or

injured,‖―incapacitating illness or injury,‖ or ―not seriously

injured.‖ Also called WIA. See also casualty category.

Disease Non-Battle Injury (DNBI): A person who is not a battle

casualty but who is lost to the organization by reason of disease

or injury, including persons dying of disease or injury, by

reason of being missing where the absence does not appear to be

voluntary, or due to enemy action or being interned. Also called

DNBI casualty.

Non-Battle Injury (NBI): A person who becomes a casualty due to

circumstances not directly attributable to hostile action or

terrorist activity. Also called NBI.

Died of Wounds Received in Action (DWRIA): A casualty category

applicable to a hostile casualty, other than the victim of a

terrorist activity, who dies of wounds or other injuries received

in action after having reached a medical treatment facility. Also

called DWRIA. See also casualty category.

Killed in Action (KIA): A casualty category applicable to a

hostile casualty, other than the victim of a terrorist activity,

Class VIII Management

2-10

who is killed outright or who dies as a result of wounds or other

injuries before reaching a medical treatment facility. Also

called KIA. See also casualty category.

NHRC will utilize a robust empirical data base to establish

probability distributions across each of the five sub-categories in

order to develop patient streams. Upon conclusion, NHRC will input

these distributions into modeling systems to generate the materiel

requirements, number and type of supplies, to treat a particular

patient stream. The resulting list of materiel requirements will be

provided to LPC to submit to DLA for future sourcing.

Participants in this Requirements Determination—Surge phase are:

Defense Logistics Agency (Troop Support)

Naval Health Research Center

Deputy Commandant Installations & Logistics (DC I&L) Life Cycle

Management Branch (LPC)

Deputy Commandant Plans, Policies, and Operations (DC PP&O)

Systems in this phase are (See Chapter 9 for Systems Descriptions):

Tactical Medical Logistics Planning Tool (TML+)

a. Process Map

Class VIII Management

2-11

Requirements Determination – Surge (Strategic)

DC PP&O

(PLN)

DLA

(Troop Support)

DC I&LI

(LPC-2)

BUMED

(NHRC)

System

Start

TML+

Release message

to PP&O requesting

CASESTs for

designated

OPLANs

Receive

message and

initiate

coordination

for rate

determination

Coordinate for

determination

of 60/180

DOS

CASESTs

Coordinate for

determination

of 60/180

DOS

CASESTs

Submit 60/

180 DOS

CASESTs

Review &

submit 60/180

DOS

CASESTs

Receive HQMC

CASESTs &

input into

modeling

system

Conduct

modeling

Create HQMC

Medical

Contingency

File (MCF)

Review

USMC surge

requirements

(MCF)

Submit

HQMC MCF

for Biannual

Review

Develop

contract

coverage for

DoD surge

requirements

Host Biannual

review of

medical

contingency

requirements

End

Participate in

biannual

review &

advocate for

USMC

requirements

Publish

DML-PC

DRAFT

Previous

Phase

System

Key:

Next

Phase

Document

Process

Step

Class VIII Management

2-12

Class VIII Management

2-13

b. Process Step Descriptions

1. Release message to PP&O requesting CASESTs for designated OPLANS

Description: Based on annual requirement, DC I&L (LPC-2) create

and disseminate a Naval Message to PP&O (PLN) to request support

in generating CASESTs for designated OPLANS.

Input: Requirements Determination Timeline

Output: CASEST Naval Message

2. Receive message and initiate coordination for rate determination

Description: DC PP&O receive message from DC I&L (LPC-2) and

conduct preliminary analysis required to support the development

of CASEST rates. The preliminary analysis includes an

examination of current Defense and Marine Corps guidance on

considerations for parameter data, as well as planning factors

such as conflict intensities (LIC, MIC, HIC) and DNBI, as defined

above in the introduction to this section.

Input: CASEST Naval Message

Output: Preliminary Analysis

3. Coordinate for determination of 60/180 DOS CASESTs

Description: DC PP&O coordinate with DC I&L (LPO-1/LPC-2) in

order to determine the appropriate CASEST rate for a 60/180 DOS

capability in accordance with the four elements (LIC, MIC, HIC,

and DNBI) defined above in the introduction to this section.

Input: Preliminary Analysis

4. Submit 60/180 DOS CASESTs

Description: DC PP&O (PLN) submit 60/180 DOS CASESTs to DC I&L

(LPC-2) for review.

Output: 60/180 DOS CASESTs

5. Review and submit 60/180 DOS CASESTs

Description: DC I&L (LPC-2) review the CASEST provided by DC

PP&O and make any required adjustments prior to submitting to

NHRC. Upon approval, LPC-2 submit to NHRC.

Input: 60/180 DOS CASESTs

Output: Adjusted 60/180 DOS CASESTs

6. Receive HQMC CASESTs and input into modeling system

Description: BUMED (NHRC) receive HQMC CASESTs and input into

TML+ modeling system.

Input: Adjusted 60/180 DOS CASESTs

Class VIII Management

2-14

7. Conduct modeling

Description: BUMED (NHRC) conduct modeling in TML+. NHRC run the

patient streams in terms of volume and type of injury. Utilize

the model to determine, based on a statistical variables, the

patient stream. Based on this data, determine the associated

AMALs, number of supplies required to treat the patient stream

identified, and generate surge requirements.

Important Note: This process applies to consumable re-supply only

and does not address equipment.

Input: CASEST into TML+

Output: Surge Requirements

8. Create HQMC Medical Contingency File (MCF)

Description: BUMED (NHRC) create HQMC MCF. DC I&L (LPC-2)

participate in this process, along with MCSC (PM CSE), to ensure

that NSNs in the Marine Corps inventory align with the MCF.

Additionally, DC I&L (LPC-2) identify items that are coded ―Y‖

(items that are no longer manufactured but may still be in the

Marine Corps inventory) and determine appropriate substitutions

for replenishment of these items.

Input: Surge Requirements

Output: Draft MCF

9. Review USMC surge requirements (MCF)

Description: BUMED (NHRC) send final MCF to DC I&L (LPC-2) for

review. DC I&L (LPC-2) coordinate with MCSC to ensure all NSNs

associated with the surge requirements are valid. Modify as

appropriate to generate the Adjusted MCF.

Input: Draft MCF

10. Submit HQMC MCF for Biannual Review

Description: DC I&L (LPC-2) submit HQMC portion of the MCF to

DLA (Troop Support) for incorporation with the other service

requirements at the Biannual Review.

Important Note: The MCF is submitted annually in January/July

Output: Final MCF

Class VIII Management

2-15

Figure 8.13 Requirements Determination—Surge (Strategic) Activities

11. Host Biannual Review of medical contingency requirements

Description: Defense Logistics Agency (DLA) (Troop Support) host

Biannual Review of medical contingency requirements. This effort

is supported DC I&L (LPC-2), who participates in the Biannual

Review and advocates for USMC requirements. During the review,

requirements are vetted across all services to ensure

requirements are valid and can be supported by contingency

contracts. A priority is set for items that support multiple

services.

Input: Individual Service MCF

Output: Consolidated MCF

12. Develop contract coverage for DoD surge requirements

Description: DLA review the current contingency contracts in

place to ensure coverage associated with the newly-established

requirements and award contracts for new surge requirements.

Input: Consolidated MCF

13. Publish DML-PC

Description: DLA publish Defense Medical Logistics-Proponent

Committee. The committee involves participants from all

services, who review the status of all contingency files. DML-PC

publish a report at the conclusion of the committee, which covers

the status of contingency files and DLA’s percentage capability.

Output: DML-PC Report

Class VIII Management

3-1

NAVMC 4000.2

Class VIII Management

Selection Criteria

Chapter 3

Class VIII Management

3-3

A. Selection Criteria

Selection Criteria, in conjunction with the Requirements Determination

function described in the following chapter, parallels the Plan Health

Service Support phase of the NAVMEDLOGCOM process for determining

medical support requirements.

The Marine Corps AMALs/ADAL are designed to establish and/or support a

specific health care mission. These health care missions will be

influenced by factors such as fluctuations in combat intensity,

evacuation policies and capabilities, and availability of non-organic

health care support (i.e., Navy Expeditionary Medical Facilities

(EMFs), host nation support, etc). The Marine Corps has established a

process, the Modernization Review, to review the method by which

Medical Materiel is updated to reflect current treatment protocols and

modalities in order to improve operational medical readiness to the

warfighter by fielding improved Medical Materiel.

1. Modernization Review

The Modernization Review is an extensive process and is used to ensure

use of the most-up-to-date equipment and consumables. Individual

AMALs/ADAL are reviewed on a four-year cycle.

Participants in this phase are (See MCO 4400.39, Chapter 8, for

overall roles and responsibilities):

Deputy Commandant Installations & Logistics (DC I&L) Life Cycle

Management Branch (LPC)

Deputy Commandant Combat Development & Integration (DC CD&I)

Integration Division (ID)

Commanding General Marine Corps Systems Command (CG MCSC) Program

Manager, Combat Support Equipment (PM-CSE)

Naval Health and Research Center (NHRC)

Blount Island Command (BIC)

Marine Forces Command (MARFORCOM)

Marine Forces Pacific (MARFORPAC)

Marine Expeditionary Forces (MEFs)

Marine Forces Reserve (MARFORRES)

Systems used in this phase are (See Chapter 9 for Systems

Descriptions):

Medical Logistics Online (MLO)

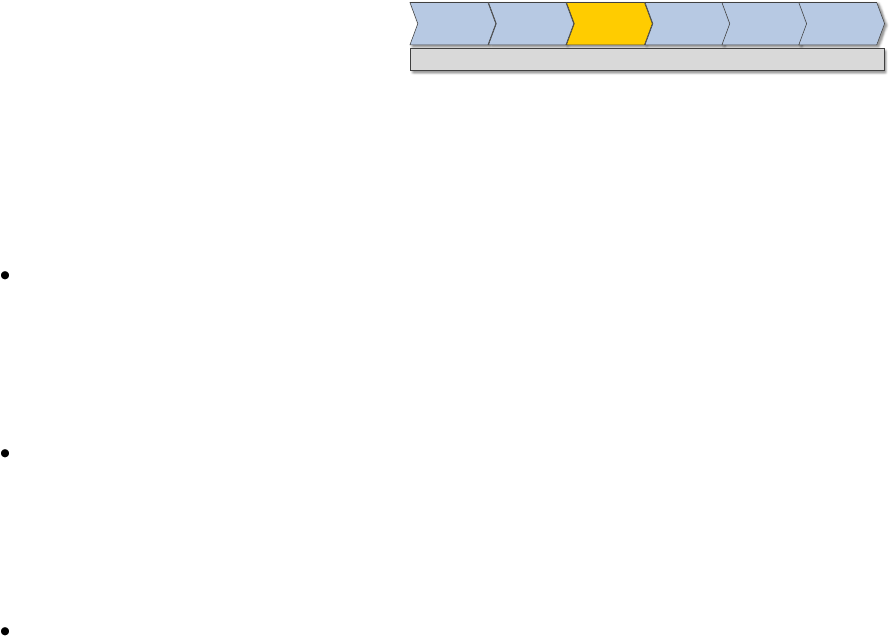

Total Force Structure Management System (TFSMS)

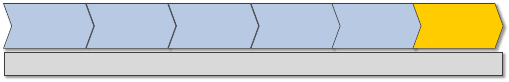

Selection

Criteria

Requirements

Determination

Sourcing Positioning Acquisition Distribution

Management

Class VIII Management

3-4

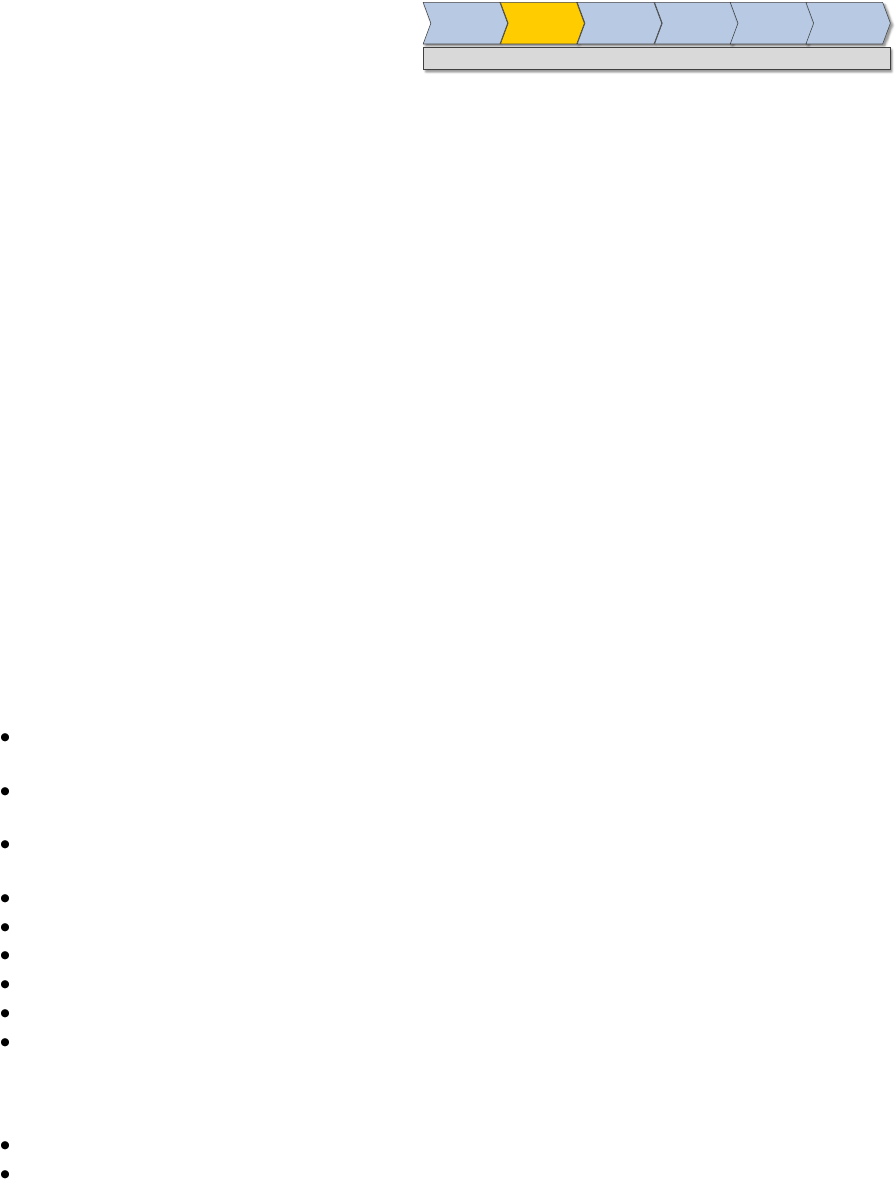

a. Process Map

Figure 8.7 Modernization Review

P o s t - R e v i e w

M od er ni za ti o n Re vi ew

P r e - R e v i e w R e v i e w

D C C D & I

( C D D /L ID / N S B )

S y s t e m

M E F /

M A R F O R R E S

( M L G )

M A R F OR

B I C N H R C

C G M C S C

( P M CS E)

D C I & L

( L P C )

C r e a t e & S u b m i t

A M A L R e v i e w

S u m m a r y R e p o r t

C r e a t e & r e l e a s e

R e v i e w m e s s a g e

P a r t i c i p a t e i n

A M A L s / A D A L

R e v i e w

P a r t i c i p a t e i n

A M A L s / A D A L

R e v i e w

M L O

P r o v i d e

a t t e n d e e l i s t

D e v e l o p

r e v i e w

s c h e d u l e &

t a i l o r c h e c k l i s t

C o n d u c t P o s t -

R e v i e w

m e e t i n g

C o n d u c t P o s t -

R e v i e w

m e e t i n g

R e c e i v e

A M A L R e v i e w

S u m m a r y

R e p o r t

C o o r d i n a t e

p o s t - R e v i e w

w i t h

d e s i g n a t e d

a t t e n d e e s

C o n d u c t P r e -

R e v i e w

m e e t i n g

P r o v i d e

a t t e n d e e l i s t

C o n d u c t P o s t -

R e v i e w

m e e t i n g

P r o v i d e

a t t e n d e e l i s t

C o m p i l e

R e a d - a h e a d s

a n d d i s t r i b u t e

t o p a r t i c i p a n t s

S y s t e m

R e v i e w 4 y r

A M A L

s c h e d u l e f o r

u p c o m i n g

f i s c a l y e a r

C o o r d i n a t e

P r e - R e v i e w

w i t h

d e s i g n a t e d

a t t e n d e e s

P a r t i c i p a t e i n

A M A L s / A D A L

R e v i e w

C o n d u c t P o s t -

R e v i e w

m e e t i n g

M L O

E n d

L e a d

A M A L s / A D A L

M o d e r n i z a t i o n

R e v i e w

P a r t i c i p a t e i n

A M A L s / A D A L

R e v i e w

P o s t c u r r e n t

l i n e l i s t

M L O

C o n d u c t P r e -

R e v i e w

m e e t i n g

S t a r t

P r o v i d e

a t t e n d e e l i s t

P a r t i c i p a t e i n

A M A L s / A D A L

R e v i e w

M L O

P a r t i c i p a t e i n

A M A L s / A D A L

R e v i e w

P r o v i d e

a t t e n d e e l i s t

C o n d u c t P r e -

R e v i e w

m e e t i n g

P l a n t h e

R e v i e w

P r o v i d e

a t t e n d e e l i s t

C o n d u c t P o s t -

R e v i e w

m e e t i n g

C o n d u c t P o s t -

R e v i e w

m e e t i n g

C o n d u c t P r e -

R e v i e w

m e e t i n g

C o n d u c t P r e -

R e v i e w

m e e t i n g

C o n d u c t P r e -

R e v i e w

m e e t i n g

C o n d u c t P r e -

R e v i e w

m e e t i n g

C o n d u c t P o s t -

R e v i e w

m e e t i n g

R e c e i v e

R e v i e w

M e s s a g e

R e c e i v e

R e v i e w

M e s s a g e

R e c e i v e

R e v i e w

M e s s a g e

R e c e i v e

R e v i e w