STADIUM SEATING ENTERPRISES

PREFOAM™

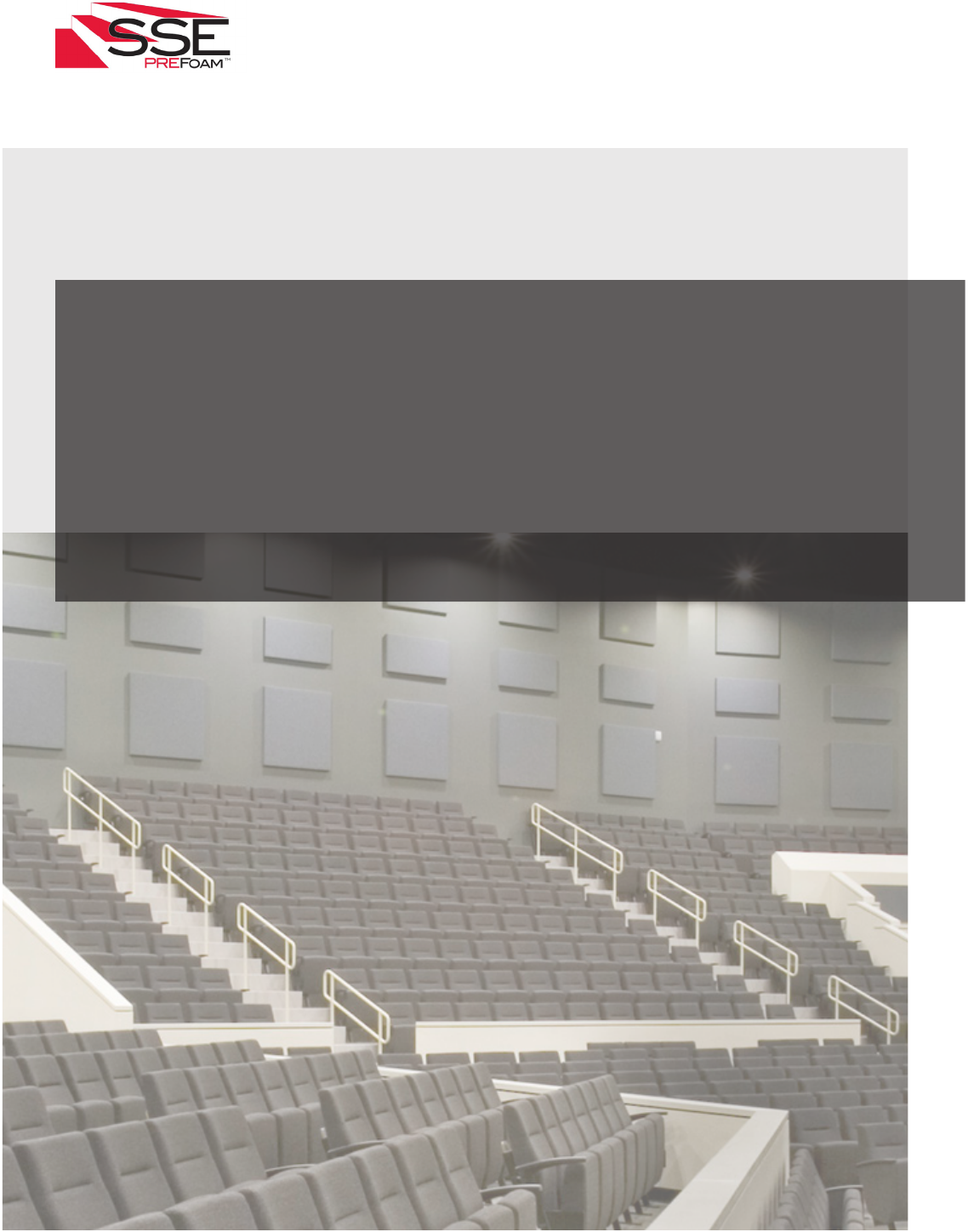

Stadium Seating

Stadium Seating Enterprises, Inc.

Sky Park Court, Suite 250

San Diego, CA 92123

2

Stadium Seating Enterprises

CONTENTS

PREFOAM System Installation

PREFOAM System Advantages

Manufacturing Partnerships

PREFOAM Clients

Enviromentally Responsible

page 3

page 6

page 7

page 9

page 13

All information contained in the package is proprietary and the property of

Stadium Seating Enterprises, Inc. Reproduction of any information contained in this package

or distribution of this information to any individual or company without the express written

permission of SSE is strictly prohibited.

2 3

Stadium Seating Enterprises

SYSTEM INSTALLATION

The SSE PREFOAM

Permanent Stadium Seating Riser

Systems are the fastest, easiest and most cost effective

method of constructing stadium seating on the market

today. Traditional methods of constructing stadium ris-

ers have used structural steel stud and pan framing or

plywood formed concrete framing. With the develop-

ment of the SSE PREFOAM Systems, the industry has

recognized that a prefabricated and pre-engineered

foam riser system saves time and money in the con-

struction of permanent stadium seating.

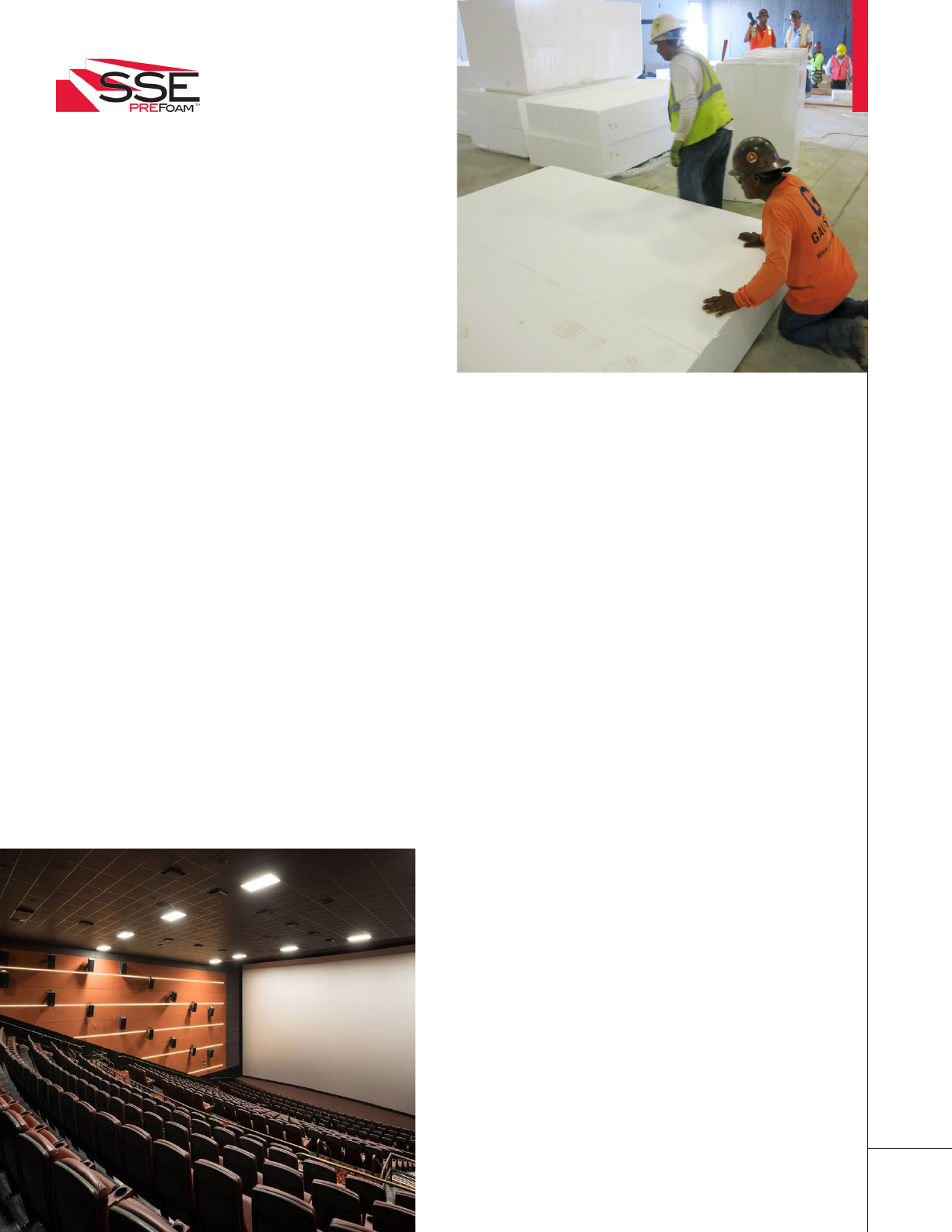

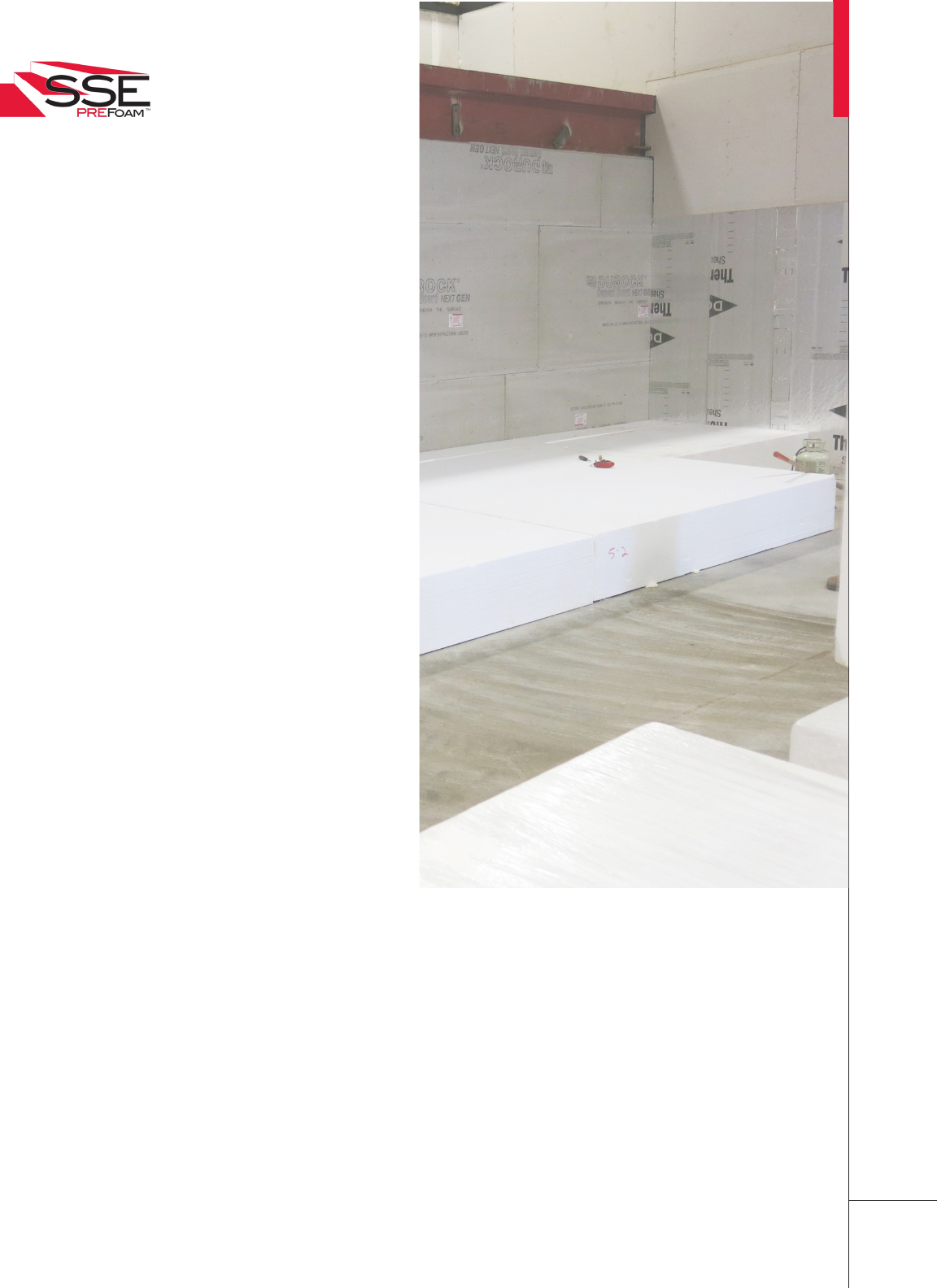

Developed as a pre-engineered “kit of parts” for stadi-

um seating risers, the PREFOAM Systems incorporate

blocks of EPS Geofoam cut to the dimensions of the

stadium platforms that are stacked like building blocks

to form the tiered seating risers. After the blocks are put

in place, the permanent steel forms are placed along

the face of the risers and secured with steel “retainer”

hardware. Then, prefabricated steel intermediate step

forms are secured to the vertical face of the risers to

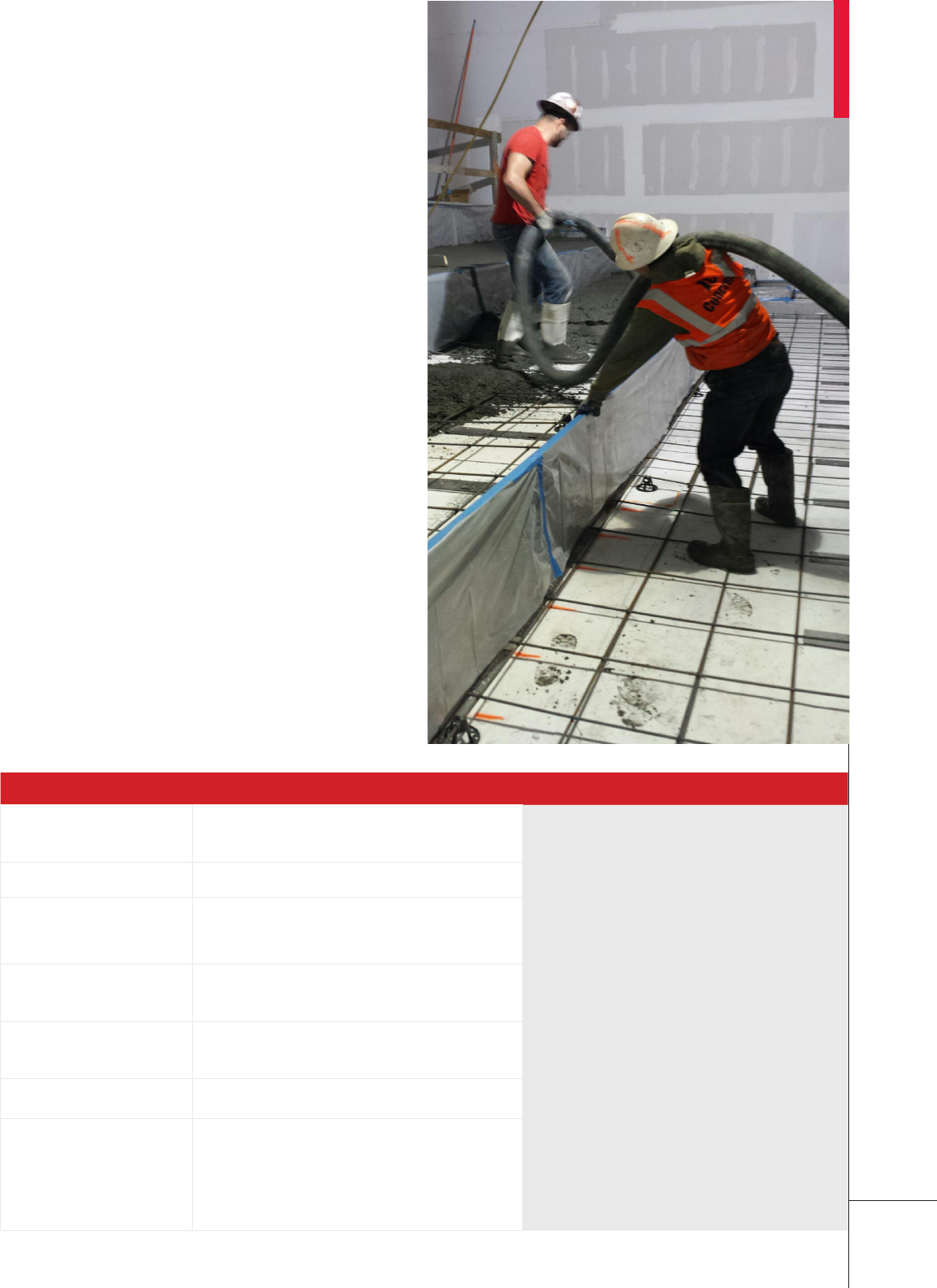

complete the “bones” of the system. Last, as a nishing

oor material, concrete used for the horizontal surface

of the stadium platforms and the intermediate steps is

poured directly on top of the PREFOAM blocks.

The system comes with a complete detailed set of in-

stallation instructions and shop drawings illustrating

each area to receive the PREFOAM System. To facilitate

easy installation, EPS blocks and steel components are

clearly marked with a specic code referenced in the

installation drawings.

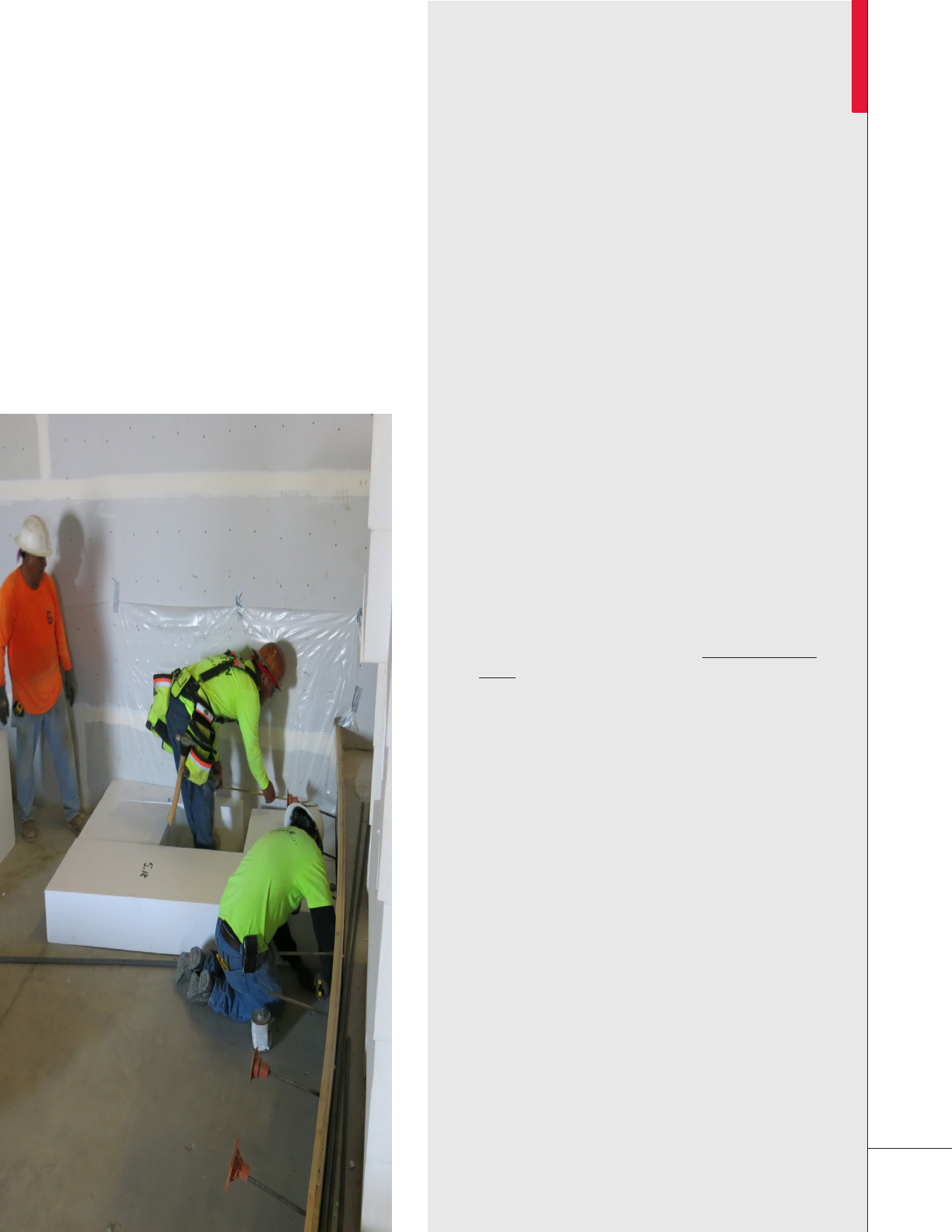

• The PREFOAM System can typically be installed by

the contractor, ready for topping concrete in as little as

1 - 2 days per auditorium utilizing general labor; that is

4 to 5 times faster when compared to the time required

to install a light gauge metal frame and pan system;

• The PREFOAM System is installed late in the con-

struction sequence, allowing all high work to be com-

pleted in the auditorium, sanctuary, theatre, lecture hall

or corporate screening/presentation rooms without the

need to scaffold over the tiered seating platforms;

• The PREFOAM System can easily be designed to

accommodate space under the platorms by stacking

block up to and on top of a light gauge metal frame and

structural deck;

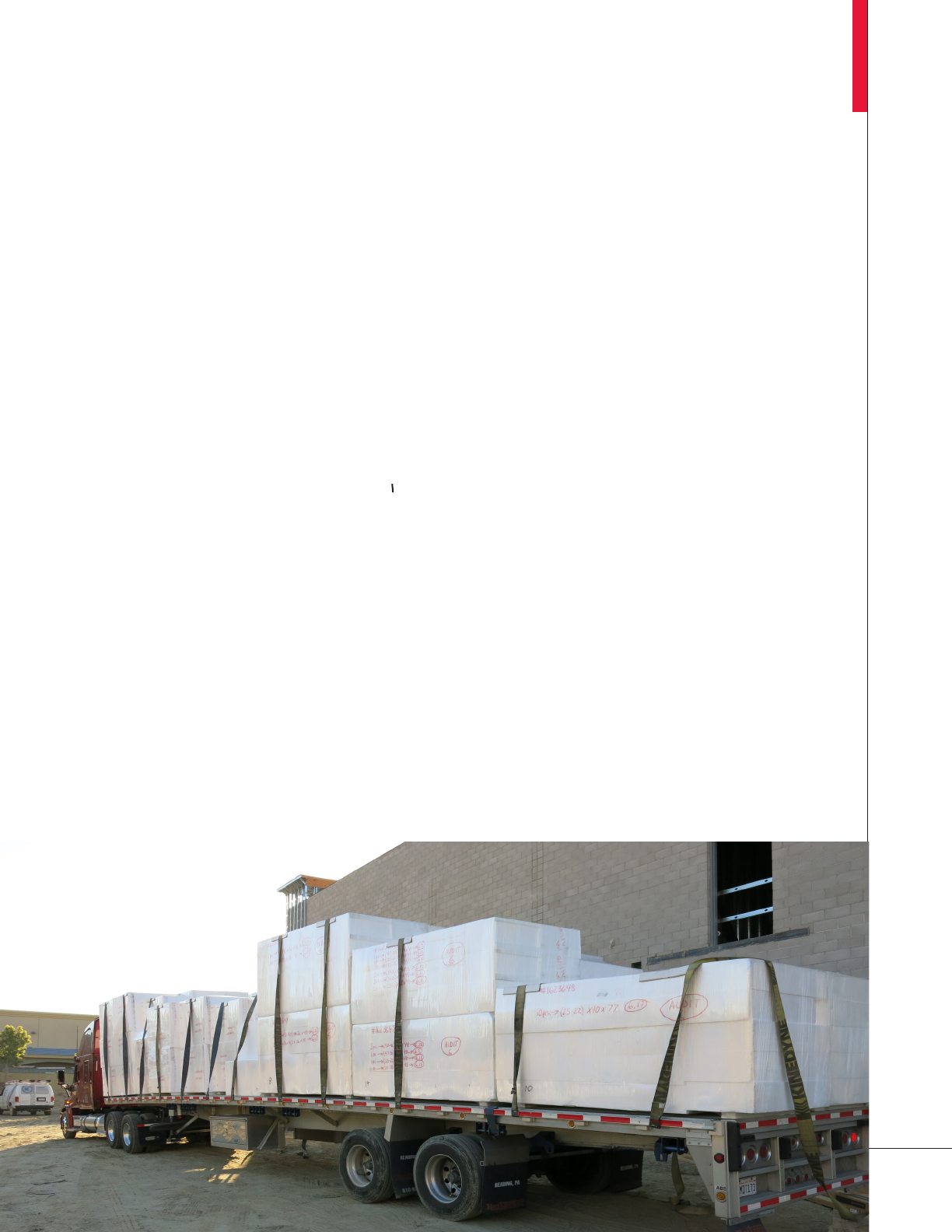

• The PREFOAM System is delivered to the jobsite with

all steel components precut to the dimensions of the

stadium platform criteria;

• Because of the proprietary intermediate step forms,

the PREFOAM System is designed to allow the concrete

subcontractor to pour the entire platform in a single op-

eration. Traditional methods require a second pour for

the intermediate steps.

• The PREFOAM System includes all 12 or 16 gauge

steel riser permanent riser forms, connecting hardware

and intermediate step forms;

• Most PREFOAM blocks come numbered and precut

to the size and shape of each riser tread;

• All steel components are assembled using #10-1”

self tapping sheet metal screws.

4

Stadium Seating Enterprises

PREFOAM System vs

Traditional Stud Steel Framing

Traditional steel stud framing for stadium seating riser

platforms can take 4-5 days per auditorium to install.

Steel stud framing is an assembly of light gauge steel,

metal pans and closure plates mostly fabricated and as-

sembled by manufacturers and trades without one sin-

gle subcontractor or vendor maintaining responsibility

for the entire system.

• SSE’s PREFOAM system is designed and fabricated

under the direction of one company; SSE.

• The pre-engineered system is delivered to the jobsite

ready for installation by the general contractor. Typical-

ly, the entire system can be installed and ready for the

concrete topping slab in approximately 1– 2 days per

auditorium.

• The installation of the SSE PREFOAM system can

save weeks off the construction schedule and as much

as 20 – 25% in costs.

When comparing the cost of traditional multi-trade steel

stud framing to a complete SSE PREFOAM system don’t

forget to evaluate all the factors involved in each meth-

od. The chart below provides an overview and compari-

son of the two systems. It is easy to see why the SSE Sys-

tem is preferred over the traditional steel stud system.

Item Traditional Stud Steel Framing SSE PREFoam System

Installation Contractor Drywall & Concrete Sub General Labor or Concrete Sub

Installation Time 4 - 5 days per auditorium 1 - 2 days per auditorium

Stadium Structure Light gauge steel framing assembled in the

eld by drywall subcontractor

Prefabricated EPS Geofoam Blocks, coded

and delivered to the jobsite ready for instal-

lation. Installed by general labor.

Steel “Riser Plate” Independent steel subcontractor and in-

stalled by drywall subcontractor

Prefabricated, coded and delivered to the

jobsite. Installed by general labor.

“Pans” for Concrete Slab Independent steel subcontractor and in-

stalled by drywall subcontractor

Not Required

Concrete Topping Slab By concrete sub By concrete sub

Intermediate Steps Steps are formed and poured in the eld (2

pours required). By concrete subcontractor.

Prefabricated and delivered to the jobsite

ready for installation and concrete pour.

Single pour for complete system installation

including intermediate steps.

5

Stadium Seating Enterprises

The SSE PREFOAM Stadium Riser System provides

general contractors, architects, and owners with a

solution that will enable them to go from a “nished

shell” to a nished auditorium in weeks, not months.

Builders, architects and owners alike are striving to

reduce costs, shorten schedules and improve the

quality in the most effecient way possible. Using a

custom pre-engineered and prefabricated system of

PREFOAM EPS and 12 or 16-GA steel, SSE offers

it’s customers an alternative to costly and time con-

suming traditional methods of installing tiered sta-

dium seating platforms.

One of the distinct advantages of the SSE PREFOAM

System is the fact that it is custom prefabricated and

delivered to the site ready to be installed late in the

construction sequence following the stud and dry-

wall completion of the auditorium’s demising, back

and vomitary walls. Because the general contractor

can work on a oor unencumbered by scaffolding,

the ability to get the auditorium “stadium ready” pro-

ceeds much more effeciently than can be realized

using traditional metal stud construction.

In a typical installation, ninety percent of the EPS

block is delivered to the project site precut to the

platorm dimensions (width, height and length) and

slope (if any) of the existing oor slab. Consistent

with the SSE shop drawings, blocks are pre-marked

for direct placement on the auditorium oor. Each

of the EPS blocks is marked by auditorium number,

platform level, row and block location in each row of

the auditorium.

As the EPS blocks are stacked in their respective

positions, a small amount of special EPS adhesive

or “Gripper Plates” are used to hold them in place

until the riser plates and connecting hardware are

installed. By the afternoon of the rst day of instal-

lation, typically the work crew is busy installing the

12 or 16-gauge steel riser plates and connecting

hardware. The riser plates not only serve to nish

the face of the platform riser, but also serve as a

form for pouring the 4” concrete platform deck. They

are held securely in place with connecting hardware

placed every 24” on-center.

6

Stadium Seating Enterprises

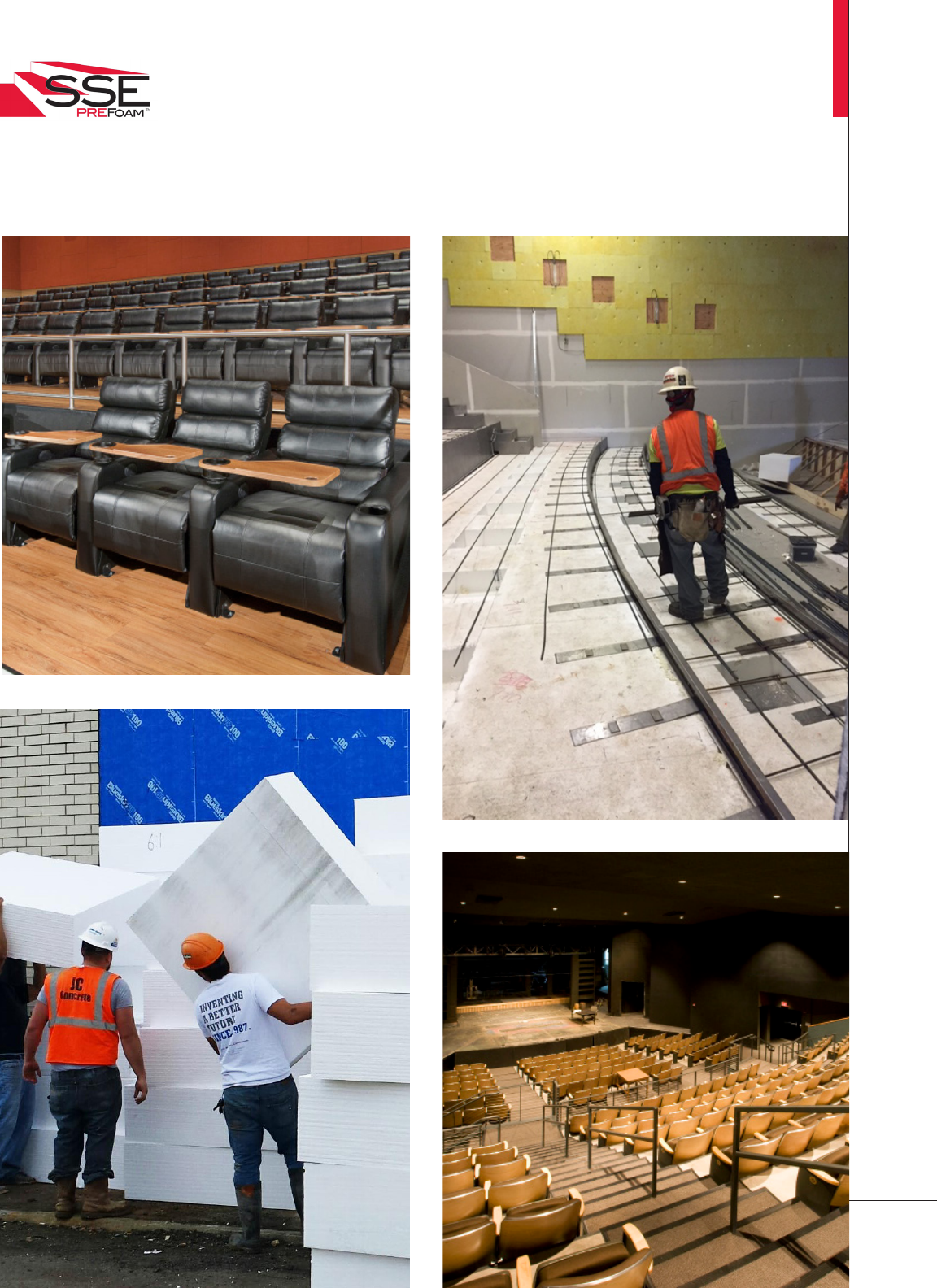

One of the advantages that the PREFOAM System of-

fers the Design Architect is layout and seating cong-

uration exibility. Because each system is custom de-

signed to meet the individual criteria of the project, the

EPS blocks can be cut into virtually any size, height or

shape. And the height and depth of each individual riser

or intermediate step is also “made to order.” Depend-

ing upon the design concept and shell building layout,

the stadium seating can be congured in straight, seg-

mented radius or true radius rows.

Space Under the Platforms

The inclusion of stadium style seating platforms can

also lend itself to maximum utilization of oor space. In

many cases, the overall height of the top platforms will

allow usable space to be “tucked in” under the back of

the stadium risers. By incorporating space under the

risers, the effecient use of the overall oor area can

be maximized. Typical spaces under the stadium riser

platforms include storage rooms, concessions, ofces,

classrooms, restrooms or similar functions.

Ramps and Stages

The PREFOAM blocks are ideal for constructing ramps

for handicap or equipment access. Tapered precut

blocks are delivered to the jobsite ready for placement

and topping with a 3”- 4” concrete slab. If the project

includes an elevated stage at the front of the audito-

rium or sanctuary, the use of PREFOAM blocks is ideal

for elevating the stage. PREFOAM blocks are simpler,

more cost effective and easier to use in the stage’s con-

struction compared to traditional metal stud and deck

construction. The PREFOAM blocks are set in place

as a structural ll material within the perimeter stage

walls and the topping slab is poured over the PREFOAM

block. Electrical, data or other conduit can easily be in-

corporated into the PREFOAM ller material.

An Environmentally Friendly Solution

Because EPS material is resource effecient, can be

made with partially recycled material, and is energy ef-

fecient for insulation. The incorporation of the

PREFOAM System is an environmentally friendly stadi-

um seating solution for any project.

SYSTEM ADVANTAGES

Balcony/Upper Floor Stadium Seating

The use of PREFOAM blocks is an ideal structural solu-

tion for balcony stadium risers. Weighing one pound

per cubic foot, PREFOAM is extremely lightweight. One

4’-0” x 8’-0” x 12” thick block of EPS weighs approxi-

mately 32 lbs. The individual blocks are easily carried

by a single person and can be taken through a stan-

dard pedestrian door and put in place on an upper level

balcony without any special equipment or extraordinary

considerations. In addition, due to the geometry of the

block, the weight of the stadium risers is evenly distrib-

uted over the entire balcony oor area eliminating any

point load.

6 7

Stadium Seating Enterprises

MANUFACTURING PARTNERS

UNITED KINGDOM

JAMAICA

HAWAII

8

Stadium Seating Enterprises

SSE PREFOAM

TM

Regional “Partnerships” Promote Responsive Service

Since our founding in the late 1990’s, Stadium Seating Enterprises, Inc. (SSE) has focused on providing the most

professional and responsive service available in the industry. Two principals that have shaped our success and

growth over the years are the unwavering commitment to personal service from SSE ownership and the develop-

ment of an integrated delivery process between our designers and our manufacturing and fabrication partners.

Key to our success and responsive- ness are the “partnerships” we have fostered between our EPS Geofoam

Manufacturing and our Specialty Steel Fabrication Companies and SSE’s team of system designers, engineers

and project managers.

We have worked diligently to integrate our “partners” into our design and delivery process insuring that each of

them is experienced with the SSE PREFOAM Stadium Seating Riser System and committed to providing the same

level of service that SSE Customers have enjoyed over the past decade.

The adjacent map locates our major manufacturing and fabrication partners. The dots identify the location of our

EPS and Steel Fabrication Partners. From these locations, SSE can bring cost competitive and responsive service

to our customers and minimize environmental impact through better logistical distribution of our products. SSE

can deliver Geofoam or our complete PREFOAM Stadium Seating Riser System to virtually any location in the

continental US within approximately one day’s drive of the manufacturer/fabricator.

MANUFACTURING PARTNERS

United States

• Arlington, TX

• Aurora, CO

• Belgrade, MT

• Brooklyn Park, MN

• Byron Center, MI

• Carlisle, PA

• Chino, CA

• Cicero, NY

• Columbus, OH

• Conyers, GA

• Denver, CO

• Des Moines, IA

• Dixon, CA

• Fredericksburg, VA

• Gainsville, GA

• Grandville, MI

• Hillsboro, TX

• Houston, TX

• Jacksonville, FL

• Kansas City, KS

• Kapolei, HI

• Kingman, AZ

• Lakeland, FL

• Lakeville, MN

• Lebanon, OH

• Manassas, VA

• Mead, NE

• Monticello, AR

• Mt. Pleasant, SC

• Murry, UT

• Little Rock, AK

• Orlando, FL

• Pensacoloa, FL

• Perryville, MO

• Phoenix, AZ

• Plymouth, WI

• Prior Lake, MN

• Puyallup, WA

• Rochester, NY

• Rockford, MN

• Roseville, CA

• Sallisaw, OK

• Smitheld, RI

• Smitheld, PA

• Solon Springs, WI

• Tacoma, WA

• Washington, IA

• Watertown, SD

• Whiteland, IN

• Wilsonville, OR

• Winchester, VA

•

Austin, TX

• Columbus, OH

• Middletown, OH

• Myerstown, PA

Canada

•

Acheson, AB

• Midland, ON

• Saint-Laurent, QC

Carribean/Mexico

•

Kingston, Jamaica

•

Colonia, Mexico

• Culiacan, Mexico

• Tijuana, Mexico

United Kingdom

• Northhampton, AR

EPS Foam Manufactures

Steel Manufactures

• Haltom City, TX

• Logan, UT

• Oldcastle, ON

• Santee, CA

• St. Paul, MN

• Tavares, FL

• West Valley, UT

8 9

Stadium Seating Enterprises

SSE PREFOAM CLIENTS

10

Stadium Seating Enterprises

Representative

Architects

5G Architects

ADW Architects

Algier Group Architects

Althouse, Jaffe & Associates

BGW Architects

Baker Barrios Architects

Beck Group

Blair Ballard Architects

Calvert Architectural Group

Cannon Moss Associates

Carlos Moore Architect

The Design Collective

Design West Architects

DLR Group

DMJM AECOM

dva Architects

ELS Architects

FFKR Architects

FTCH Architects

Fleming Associates

Gantt Huberman Architects

Haas Architects

Hoefer Wysocki Architects

Hodges & Associates

Hurford Architects

JKR Architects

Kenneth D Smith Architects

Kinslow

Keith & Todd

Level 4 Studio

Lickel Architecture

MDN Architects

Mesbur + Smith Architects

Panich + Noel Architects

Partners in Architecture

Perkins & Will

Pustola & Associates

RL Payne & Associates

RTA Architects

Rodney Sartain Architect

Roth Shepard Architects

TK Architects International

Tennant Wallace Architects

Thomas Hacker Architects

United Church Builders

Visioneering Studios

WLC Architects

Over the past fteen years Stadium Seating Enterprises, Inc has had the op-

portunity to work with a wide variety of clients throughout the world. We have

provided our PREFOAM Stadium Seating Riser System designs for Architects,

General Contractors, Subcontractors and Facility Owners within a wide variety

of building types including Cinemas, Worship Facilities, Live Entertainment,

Educational Facilities and Corporate Training Facilities. In each case, we have

taken pride in our responsive service, professional interaction, ability to meet

stringent budget and time constraints and innovative design solutions.

Because the SSE team is composed of professionals with backgrounds in

engineering, construction and architecture we are able to respond to design

professionals in an collaborative manner that is focused on providing the best

possible solution to the design criteria. Once the initial layout of the tiered

seating is complete, the SSE team will work from the design development

stage providing alternative ideas regarding the system assembly and methods

of achieving economy and functionality for the client. Our staff can supply

AutoCAD details to the design team for integration into the nal bid package

in order to provide a complete and detailed solution to the bidding contractors

and experience providing engineering designs and calculations for the SSE

PREFOAM Systems as required by the jurisdiction of the project.

SSE installation shop drawings are fully developed for each component and

each level of the stadium seating so that no additional design for the stadium

risers is required by the A/E Team. This approach will reduce design costs for

the Architect and the Client and contributes to a comprehensive solution to

the stadium seating riser system design. In addition, if structural engineering

design is required for the stadium seating riser system, SSE can facilitate the

incorporation of outside registered professional engineering consultants to be

added to the team that have specic experience providing engineering designs

and calculations for the SSE PREFOAM Systems as required by the jurisdiction

of the project.

I cannot recommend SSE more highly. Frank and I began working

together around 2005 on a stadium seating retrot project where SSE orches-

trated the new seating concept into a reality for a general contractor unfamil-

iar with the system. He was attentive to the details of all aspects of the work

and explained carefully what and how things needed to be done in order to

accomplish the nished product.

Since, SSE has participated in several of our projects including new builds. No

one is more responsive to your questions in way that makes you feel like you

are part of a team all pulling in the same direction.

Jack Muffoletto, AIA,

Principal

TK Architects International

11

Stadium Seating Enterprises

This was our rst cinema construction project and our rst experience with

SSE. Stadium Seating Enterprises was there during every aspect of the design

and construction. They were extremely helpful and informative from the mo-

ment I contacted them, through the design process with our architect and the

installation process with our contractor. The PREFOAM System was installed

just as the said it would be based on the detailed shop drawings. Even for

a few rst-timers like us, the system went together fast & easy

and without a hitch.

We are planning to expand our theater in the future and, rest assured, we will

be back to work with SSE when the time comes. I would highly recommend

SSE to any owner, contractor or architect involved with a stadium seating proj-

ect. We look forward to working together again.

Cathy Collins, Owner

Parkway Cinemas

The fact that SSE has in house architects, engineers and contractors we are

able to integrate our professionals with the owner’s design and construction

team to facilitate a clear and comprehensive understanding of the PREFOAM

Stadium Seating Riser System. Having worked with a wide variety of owners in

the Cinema, Worship, Educational, Government, Corporate and Live Entertain-

ment industries, SSE realizes that diverse project types and clients can require

a different approach to meet their specic needs and requirements. Our ability

to service this variety of clients requires the personal attention of our owner-

ship and tailoring our services to meet every client’s specic personality and

needs. This is an approach that has characterized our company since our

inception.

The SSE PREFOAM System maximizes the productivity of the contractor that

is installed easily and quickly allowing the facility owner to occupy the lecture

halls, cinemas, or entertainment venues as soon as possible and start produc-

ing revenue or providing services long before conventional methods of con-

struction would allow. SSE can also recommend outside installation contrac-

tors with experience with the SSE PREFOAM System to work with the building

general contractor for a fast and easy installation. In many cases, SSE has con-

tracted directly with the facility owner minimizing mark-up from other entities,

or can work directly for the GC or sub handling installation of the system.

Representative Owners

Alamo Drafthouse

ArcLight Theaters

Brenden Theatres

Century Theaters

Cinemark Theatres

Cinepolis Entertainment

Cobb Theatres

Collierville Baptist Church

Colorado Cinemas

Colorado School of Mines

Dickenson Theatres

Emagine Entertainment

Epic Theatres

Flagship Cinemas

Foothills Community Church

Frank Theatres

GSA/US Army

Galaxy Theatres

Great Escape Theatres

Ipic Entertainment

Johns Hopkins University

Kerasotes Theatres

Malco Theatres

Megaplex Theatres

Northwest High School

O’Neil Cinemas

Penn Cinemas

Seacoast Grace Church

Regal Cinemas

Regency Cinemas

Revolutions Bowling

Santikos Theatres

Seacoast Grace Church

Silverspot Theaters

Skyline Community Church

Southern Theatres

Spotlight Theatres

Studio Movie Grill

Sundance Theatres

Trinity Broadcasting

Ultrastar Theatres

Universal Studios

University of California

University of Louisiana

University of Oregon

University of North Carolina

University of Tennessee

Village Centre Theatres

12

Stadium Seating Enterprises

From the initial bid to the nal close out of the construction of the Eastside

Christian Church, SSE and their team provided informed, professional and

responsive service for every aspect of the project.

SSE worked directly with the architect, general contractor and Beachside to in-

sure there was a clear understanding of the unique advantages the PREFOAM

System could bring to the project. They helped our eld crew throughout the in-

stallation with timely and responsive service. When changes were made in the

eld which affected SSE’s scope of work, they were very good at incorporating

the modications into their design and making sure we got the correct com-

ponents onsite in a timely manner. The stadium seating went together

quickly and efciently in this unique design and saved our crew

countless hours of labor in the installation process.

I would like to say thank you to the team at Stadium Seating Enterprises for

doing exactly what they said they were going to do when they said they were

going to do it. I would highly recommend Stadium Seating Enterprises to any

contractor, owner, or architect considering tiered platform seating for their

project. Now that I know about the PREFOAM system, I am looking forward to

completing many more successful projects with the SSE team.

Lou Colucci, President

Beachside Construction

Over the years we have found that Contractor and Subcontractors are some of

the biggest supporters of using the SSE PREFOAM Stadium Seating Systems.

With the SSE PREFOAM Systems every cost for the installation of the system is

spelled out from day one. There are no surprises and no hidden costs.

In more than 90% of the cases, our rst job with a contractor is the rst time

they have ever installed an EPS Geofoam stadium seating system. And, in

virtually every case, after the rst round of installations, they have concluded

that the SSE PREFOAM Systems are the most economical, easy to install and

efcient method of constructing tiered seating in the market. The SSE team

can work with the contractor to provide insight into the most efcient method

of installing the PREFOAM System.

The SSE Systems are installed in late in the construction sequence allowing

the subcontractors to nish all the high work in the platform areas without the

need to scaffold over the riser platforms. Because of the detailed SSE shop/

installation drawings and the logical assembly of the PREFOAM Systems, the

installations lends itself to the economical use of unskilled labor when appli-

cable. SSE management works in a hands-on basis directly with the general/

subcontractor’s eld crew from preconstruction through the nal concrete pour

to insure that all questions are promptly answered and the experience gained

through the installation of hundreds of systems is brought to the table. SSE

hands-on management of material delivery to the jobsite allows the contractors

to schedule “just-in-time” deliveries of the material to the jobsite.

The use of the SSE PREFOAM Systems provide benets to the entire project

team from architects and engineers to facility owners to general and subcon-

tractors. Our best references are our clients. We work hard to earn their trust,

respect and repeat business.

Representative

Contractors

AR Mays Construction

Adolfson & Peterson

Adroit Construction Co.

Baker Concrete

Biermann Construction

Blodgett Construction

Brasseld & Gorie

Breslin Builders

Canyon Building & Design

Cincinnati United Contractors

Cleveland Construction

Connell Construction

CRR Builders

Daniels & Daniels Construction

Deacon Corp.

Duke Construction

Dyson Construction

EDC

Edice Inc.

EMJ Corporation

FCI Construction Inc.

Focus Construction

Fortis Construction

Hamann Construction

Hawkins Construction, Inc.

Heath Construction Company

IKON Construction

Jaynes Corporation

KCB Construction

Linkous Construction

Luke Draily Construction

Mapp Construction

March Assoc. Construction

McCarthy Construction

Murray & Stafford Inc.

Norm Wilson & Sons

Parkway Construction

Platinum LLC

RS Mowery & Sons

Russco Construction

Sachse Construction

Specialty Construction

Sponaugle Construction

Vandervert Construction

Warfel Construction

Weitz Company

Whiting-Turner Contracting

Zapalac/Reed Construction

13

Stadium Seating Enterprises

ENVIROMENTALLY

RESPONSIBLE

There is little debate IF the incorporation of tiered

seating into your design is something that enhances

the experience of your audience. The question is HOW

should architects and builders best apply “sustainable

design principals” into the design and construction

process for this component of the building. Until re-

cently, compacted dirt ll; structural steel; precast con-

crete or structural light gauge metal framing were the

only methods of constructing tiered stadium seating.

Today there is a relatively new and innovative approach

to constructing the tiered seating risers that is not only

more efcient and economical than the traditional

methods; it is an environmentally responsible, “Green”

solution that uses recyclable material as the “building

blocks” for the tiered seating risers.

Architects, have taken on the challenge of determin-

ing how to build and furnish building’s interiors with

materials that are:

• 100% Recyclable

• Manufactured using post- consumer & post-indus-

trial materials

• ENERGY STAR qualied

• Contributes toward LEEDS credit requirements

• Free of dyes, formaldehyde and HCFCs

This section addresses one aspect of modern day

stadium seating riser system design and construction;

the design and selection of the most environmentally

friendly tiered stadium seating system available today.

This innovative SSE PREFOAM Stadium Seating Riser

System uses Expanded Polystyrene (EPS) blocks as

the structural ll material to support the tiered seating

platforms. The blocks are easily factory and eld-cut

for installation in virtually any conguration neces-

sary and provide excellent acoustic quality, and, more

importantly, the use of EPS in the PREFOAM stadium

seating system as well as its use as an insulation ma-

terial in the overall construction of the building meets

many of the criteria necessary for LEED certication.

For the tiered seating risers, it is similar to stacking

“Lego type” blocks made of EPS to form the tiered

seating platforms.

SSE is one of the leading companies in the design

industry that has taken a fresh approach to protect-

ing the build environment and employing sustainable

building practices. Over the past few years, the design

and construction professions have turned their focus

to the “Greening of America.”

The U.S. Green Building Council has developed a

nationally accepted system to rate the design, con-

struction and operations of buildings. The USGBC’s

leadership in Energy and Environmental Design (LEED)

is a standard that recognizes the life-cycle cost of

construction and helps guide the performance of proj-

ects. The LEED rating system allows owners to acquire

credits by meeting certain conditions pertaining to the

use of sustainable, energy efcient and environmental-

ly friendly products and systems.

The use of SSE PREFOAM EPS in design and construc-

tion of stadium seating for theatres, auditoriums, lec-

ture halls, live entertainment venues, and sanctuary

seating addresses each of these criteria and provides

a product that is both environmentally responsible and

a cost efcient solution to installation of tiered stadi-

um seating riser systems.

• EPS manufacturing uses minimal energy and cre-

ates nominal pollution. Steam is the primary compo-

nent in the manufacturing process and the water from

this process is collected and reused numerous times.

• With manufacturing facilities throughout North

America, EPS is manufactured in close proximity to

most building projects minimizing the distribution

radius.

• Because EPS is very lightweight, transportation

costs are minimized.

14

Stadium Seating Enterprises

Energy Efcient

• According to the U.S. Green Building Council, using

EPS in building construction helps reduce energy

consumption.

• SSE PREFOAM EPS blocks for tiered stadium

seating systems can be placed directly on compacted

ll, thus eliminating the need for a concrete slab under

the stadium seating risers. Because of the characteris-

tics of EPS, it minimizes thermal transfer, inhibits mold

growth, and is resistant to insects.

Green House Gas Reduction

EPS unlike Extruded Polystyrene (XPS) has never

utilized any greenhouse gases in the manufacturing

process and the manufacturing process itself does not

result in emissions of greenhouse gases.

In addition to the energy and environmental benets

inherent in the use of EPS, there are a large number

of efciencies that can be realized using the PREFOAM

EPS System as a construction solution for tiered stadi-

um seating.

Once the steel risers and the connecting hardware are

in place, the intermediate step forms are attached to

the face of the risers to complete the platform assem-

bly. At that point, the platform is ready for the one

continuous concrete pour of the horizontal platform

surface. This approach will typically save weeks off the

installation schedule and reduce overall costs by as

much as 20-25% compared to traditional methods.

The incorporation of a PREFOAM System is not only

more cost efcient, but also an environmentally

responsible, sustainable, “green” approach to design

and construction of tiered stadium seating risers.

Made with Recycled Material

• EPS building products can be made with recy-

cled material content. In 2004 more than 57 million

pounds of EPS was recycled.

• Tiered stadium seating systems are typically made

with approximately 10% recycled content.

• At the end of a building’s useful life, tiered stadium

seating systems constructed with SSE PREFOAM EPS

ll material can easily be removed and recycled. More

than 90% of the material in an EPS tiered stadium

seating system is comprised of recyclable EPS block

material.

• EPS does not contain harmful formaldehydes,

CFC’s or HCFC’s. The American Lung Association’s

Health House guideline acknowledges that EPS is a

safe material for insulation and structural support in

construction.

• EPS has a high degree of resistance to moisture

absorption controlling humidity and air inltration thus

reducing the development of mold.

• The use of SSE PREFOAM EPS in tiered stadium

seating design reduces vibration, reverberation and

virtually eliminates “drumming” associated with deep

base in musical performances. By minimizing audio

interference and feedback, speakers are more easily

heard and understood in large sanctuary spaces.